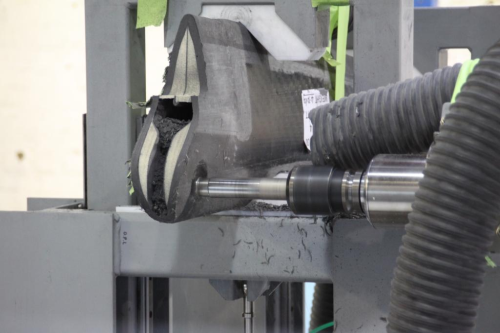

Southern Spars has acquired Delcam’s PowerMILL CAM system to program robots for the finishing of spars and other components manufactured from carbon fibre reinforced composites. The company reports savings from using robot machining in place of the traditional manual processes in the range of 70-80%. Quality and consistency have also improved substantially.

The decision to invest in the Delcam software was made by Stephen Young, a design engineer at Southern Spars with responsibility for the company’s CADCAM operations in New Zealand. He had read about the possibility of using robots to machine larger components and felt that this approach could replace the manual methods being used for finishing of the company’s composite parts.

Ease of programming was a key requirement for Southern Spars.

“All of the programming is carried out by the design office in New Zealand, plus it needed to be carried out offline as early as possible in the design process,” explains Young. “This meant that the software had to be instinctive and easy to learn. In addition, since practically every part we make has to be custom designed, the programming time had to be kept to a minimum.”

The next stage in the development is to place the robot onto rails so that even Southern Spars’ biggest components, including a 78 m mast for a superyacht, can be machined in a maximum of two sections.