Rolls-Royce has signed a contract with Italian yacht builder Benetti to deliver a lightweight steerable thruster using carbon fiber material.

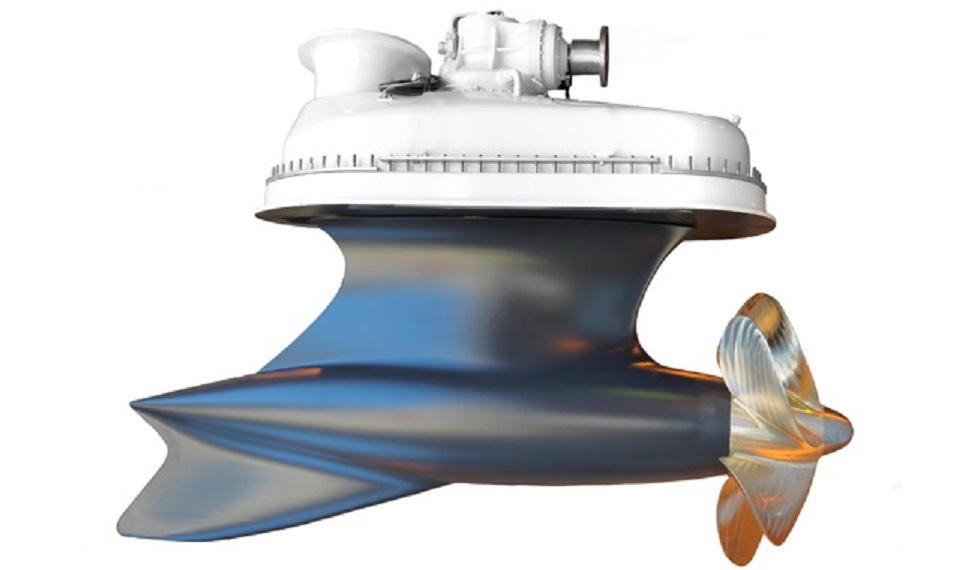

The new Azipull Carbon 65 (AZP C65) uses carbon fiber material for load carrying parts, resulting in a substantial reduction of the propulsion system’s weight, the car manufacturer says. The new thrusters also facilitate a better vessel lay out while maintaining high propulsion efficiency, improved manoeuvring capabilities and easy maintenance. It has been designed initially for fast yachts, with further applications in passenger vessels and workboats.

The first thruster in the series, AZP C65, is designed for a power rating of 2 MW and fitted with a fixed pitch, pulling type propeller. The driveline is designed with two spiral bevel gear sets, installed in a supporting structure that ensures improved load carrying capacity. The thruster can be steered using a hydraulic system. An Automation and Control system, based on Rolls-Royce’s Common Controls building blocks, has also been developed to match the new thrusters, which each weigh 2,800 kg dry.

The contract covers a number of thrusters, planned for delivery over the next three years and delivered to RINA Rules for Classification of Yachts. The first yacht, a 125 ft Fast Displacement called IRONMAN has already been delivered. Hulls two and three are under construction with delivery expected in the next few months.

This story is reprinted from material from Rolls-Royce, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.