Röchling adds that this enables machined components to be manufactured in very large dimensions.

The sheets are marketed under the brand name Durostone® have dimensions up to 12,000 mm × 950 mm and a sheet strength of 3-120 mm. Moreover, Röchling says that it is in a position to machine these sheets on CNC milling machines and to produce machined components according to customer specifications.

Durostone® sheets comprise a matrix of polyester, vinyl ester or epoxy resins and glass reinforcement – by way of example, mat or fabric, which are press moulded to a sheet under pressure and heat. Up until now, Durostone® press moulded sheets have been available in a maximum length of 6,000 mm.

Machined components in larger dimensions were therefore not producible from one sheet and had to be put together from several segments. Even longer components could only be produced from semi-finished pultruded products. However, only smaller sheet thicknesses can be attained with the pultrusion process, and the high costs for the tool required hamper economic production in smaller piece numbers.

The new length of 12 metres opens up new possibilities for design engineers, who can now utilise the benefits of composites even in applications where only conventional materials, such as metals, steel or wood, could have been used.

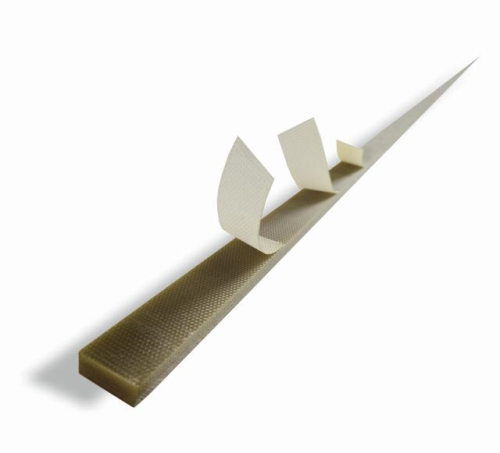

For example, for manufacturers in the electrical industry, the new dimension now enables the application of one-part peelable slot liners made of Durostone® EPC SL 38 in large generators that are at least 10 metres long.

The company adds that Durostone® can now also be used in the construction of large-size transformers. Usually compressed beams made of laminated densified wood or steel in a length of up to ten metres are used in this application. Due to its electrical conductivity within the transformer, the use of steel leads to electrical losses. Whereas compressed beams made of Durostone® are electrically insulating and at the same time have high mechanical strengths.