Premium AEROTEC exhibited a demonstrator component at the ILA Berlin Air Show (11-16 September).

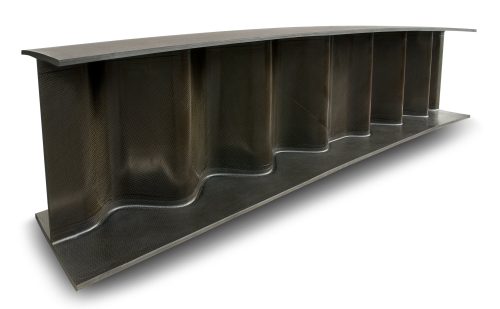

Premium AEROTEC was responsible for analysing, designing and manufacturing the demonstrator, which represents a 2.5 m-long section of a heavily loaded wing spar on a 1:1 scale. The web’s sinewaved-shaped form allows for a significant reduction in the weight of the component compared to standard spars which have monolithic or discretely reinforced even webs.

The sinewave spar was manufactured as a monolithic component using the patented Vacuum Assisted Process (VAP®) with just a single infusion cycle. Since connecting elements such as bolts, doublers or bonds are not used, this construction method enables additional weight savings (around 10% according to Premium AEROTEC’s assessment) compared to other manufacturing concepts for sinewave spars.

As well as this weight reduction, the number of components and the process and assembly steps could also be reduced considerably. This offers considerable advantages in respect of manufacturing and maintenance costs.

Premium AEROTEC develops and manufactures metal and carbon composite aerostructures. It has production plants in Germany and Romania.