Unlike commonly used natural fibres that are generally short and randomly oriented, Greenlite reinforcements are made of continuous and non-twisted cellulose fibres, resulting in high mechanical properties, explains French technical textiles producer Porcher.

Another advantage of cellulose fibres is their relatively low density of 1.5 g/cm3, compared with 2.6 g/cm3 for standard glass fibres.

This combination of low density and good mechanical properties enables the production of bio-composites with low weight and high performance.

Porcher notes that the reinforcements are particularly suited to infusion and resin transfer moulding (RTM) processes using standard or bio-based polyester or epoxy resins.

Porcher lists key benefits of Greenlite reinforcements to include:

- pure cellulose: 100% bio-based and biodegradable;

- low density for lightweight parts;

- high strength and stiffness to weight ratio compared with other natural fibres;

- very regular structure, easy to impregnate with standard processes;

- easy handling and cutting;

- high quality continuous fibres with homogenous and consistent properties;

- good compatibility with bio-based resins;

- translucency with appropriate resin systems; and

- unique look and white colour among renewable reinforcements.

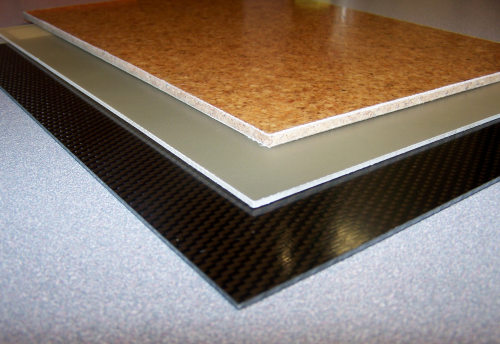

According to Porcher, Greenlite products can be combined with cork core materials to make extremely lightweight sandwich structures which possess interesting properties in terms of thermal and acoustical insulation. Greenlite reinforcements can be used in hybrid constructions with carbon fabrics, making very strong laminates while preserving the aesthetic aspect and lightness of carbon.

The Greenlite product range covers woven and unidirectional fabrics of 100-400 g/m2 which can be processed using standard equipment.