Optimised for surface finish, stiffness and impact strength, the long-fibre thermoplastic compounds are said to offer higher performance and better aesthetics than similar products for use in applications involving metal replacement and structural elements.

PolyOne’s OnForce LFT compounds retain their performance and properties in temperatures from -20°C to 160°C. The long-fibre thermoplastic compounds have improved creep and fatigue performance, better dimensional stability, good chemical resistance and surface finish when compared to highly filled short-fibre products as well as other long-fibre thermoplastics, according to PolyOne based outside Cleveland, Ohio, USA.

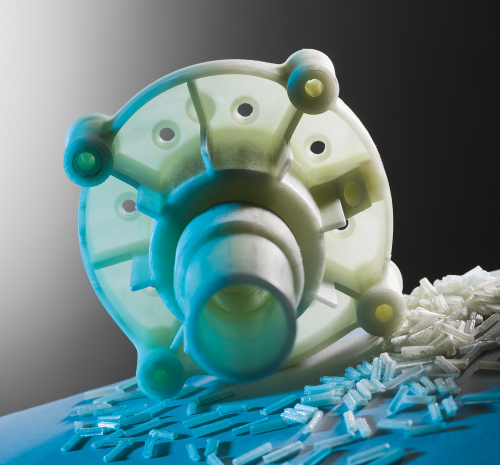

PolyOne’s OnForce LFT compounds can be processed on standard injection moulding machines.

Long-fibre compounds are currently available in a range of base polymer and reinforcement combinations including polypropylene (PP), polyamide (PA) 66, and thermoplastic polyurethane (TPU) resins combined with glass and/or carbon fibres.

The compounds can be customised with specialised fibre loading levels, customised stabilisation and additive packages, and custom colours.

Several grades are also currently in development based on engineering resins such as polyphthalamide (PPA) and polyphenylene sulfide (PPS) for higher heat applications.

The OnForce LFT platform can be used for applications including automotive powertrain, underhood, and body components, and structural industrial applications such as housing pumps, brackets and structural components.