Long fiber specialist PlastiComp Inc has recently improved its manufacturing and corporate headquarters facility in Winona, Minnosota, USA, moving its research and development functions into a dedicated laboratory space.

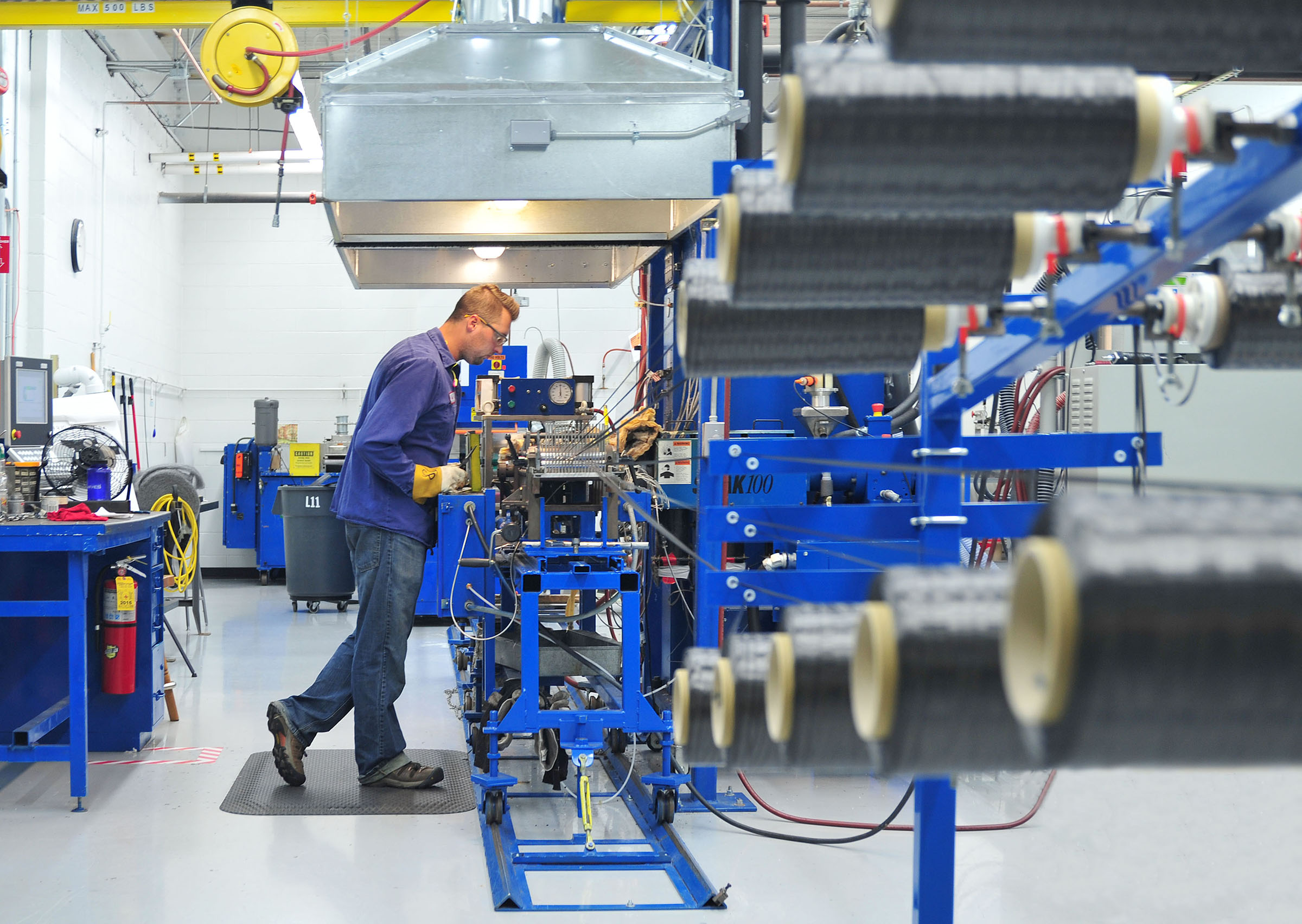

The new space will feature the company’s smaller long fiber composite pellet pultrusion line and auxiliary equipment for conducting evaluations of new raw material feedstocks and processing enhancements.

‘PlastiComp is one of the few long fiber compounders actively engaged in advancing long fiber technology into new markets and applications instead of just producing commodity long glass fiber polypropylene products,’ said Steve Bowen, president and CEO at PlastiComp. ‘Our new Da Vinci Lab provides the ideal environment for PlastiComp to evaluate different fiber and polymer combinations as well as try out new processing techniques to assess their effect on material performance.’

‘[I]t has opened up valuable floor space for future expansion that will allow PlastiComp to quickly add more composite pellet pultrusion lines as our business continues to grow,’ added Eric Wollan, vice president of technology and business development at PlastiComp.

This story is reprinted from material from PlastiComp, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.