Ottobock selected Umeco’s VTM®264 unidirectional carbon fibre reinforced epoxy resin prepregs to manufacture the blades that athletes such as Ottobock Ambassadors Heinrich Popow and Kelly Cartwright are using.

VTM264 is a toughened, 65-120°C curing prepreg developed for oven vacuum bag processing. It is an intermediate viscosity and tack prepreg suitable for full impregnation of light and medium weight unidirectional and woven reinforcements. Woven prepreg is being used for the upper section and unidirectional prepreg is being used to manufacture the blade section.

How to make a running blade

Ottobock explains that the prosthetic legs (running blades) used by runners and long-jumpers are designed to transfer the speed and energy created by the athlete onto the track.

A running blade has three main parts:

- a custom-fitted socket and liner which connects the prostheses to the athlete’s body;

- a knee joint; and

- a carbon fibre composite running blade.

Running only uses the front part of the foot (the ball), so the carbon fibre blades are designed to reproduce the function of just the forefoot and have no heel. Spikes which grip the track are fitted to the running blade.

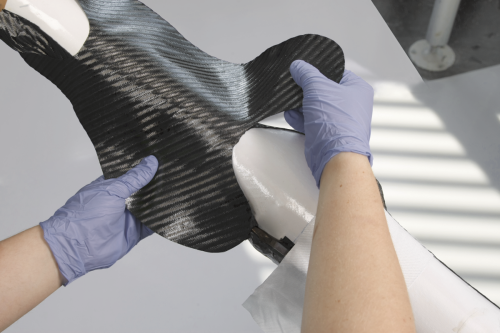

Each carbon fibre running blade is made up of more than 80 layers of carbon. Each one is laid by hand and it takes one person two hours to lay the carbon for a single running blade. The carbon fibre layers are laid one at a time over a mould. Pressure and heat are applied to fuse and harden the carbon layers. The surface of the running blade is then trimmed into shape and spikes are added.

London 2012 Paralympic Games

Ottobock, headquartered in Germany, is the Official Prosthetic, Orthotic and Wheelchair Technical Service Provider for the London 2012 Paralympic Games taking place on 29 August-9 September. Athletes competing at the London 2012 Paralympic Games will be supported by a team of 80 Otto Bock prosthetists, orthotists and wheelchair technicians.

Ottobock Ambassadors Kelly Cartwright and Heinrich Popow work with Ottobock to promote the importance of an active lifestyle for all persons with a disability and showcase the Otto Bock technology that they use in daily life and to compete in high-performance sport. Both will both take part in the London Paralympics. Australian Cartwright will be taking part in the 100 m and the long jump. German Popow will compete in the 100 m, 200 m and long jump.

- The London Paralympic Games will also see the return of the original 'Blade Runner' Oscar Pistorius, who controversially won the right to compete in the 2012 London Olympics, where he qualified for the 400 m semi-final. (See Oscar Pistorius and his controversial carbon fibre blades.)