A professor in Virginia Tech's College of Science wants to power planes and cars using energy stored in their exterior shells. He may now have discovered a path toward that vision using porous carbon fibers made from what's known as block copolymers.

Carbon fibers, already known as a high-performing engineering material, are widely used in the aerospace and automotive industries, including in the shells of luxury cars by Mercedes-Benz, BMW and Lamborghini. These thin, hair-like strands of carbon possess multiple prime material properties, being mechanically strong, chemically resistant, electrically conductive, fire retardant and, perhaps most importantly, lightweight. This means carbon fibers can help improve fuel and energy efficiency, producing faster jets and vehicles.

Guoliang ‘Greg’ Liu, an assistant professor in the Department of Chemistry at Virginia Tech, conceived the idea of creating carbon fibers that wouldn't just be structurally useful, but would also be functionally useful.

"What if we can design them to have functionality, such as energy storage?" said Liu, who is also a member of the Macromolecules Innovation Institute. "If you want them to store energy, you need to have sites to put ions in." Ideally, he added, carbon fibers would have micro-holes for storing ions of energy uniformly scattered throughout, similar to a sponge.

After tweaking a conventional method for chemically producing carbon fibers, Liu has now developed a process that can, for the first time, synthesize porous carbon fibers with pores of uniform size and spacing. He details this work in a recently published paper in Science Advances.

"Making porous carbon fibers is not easy," Liu said. "People have tried this for decades. But the quality and the uniformity of the pores in the carbon fibers were not satisfactory. We designed, synthesized and then processed these polymers in the lab, and then we made them into porous carbon fibers."

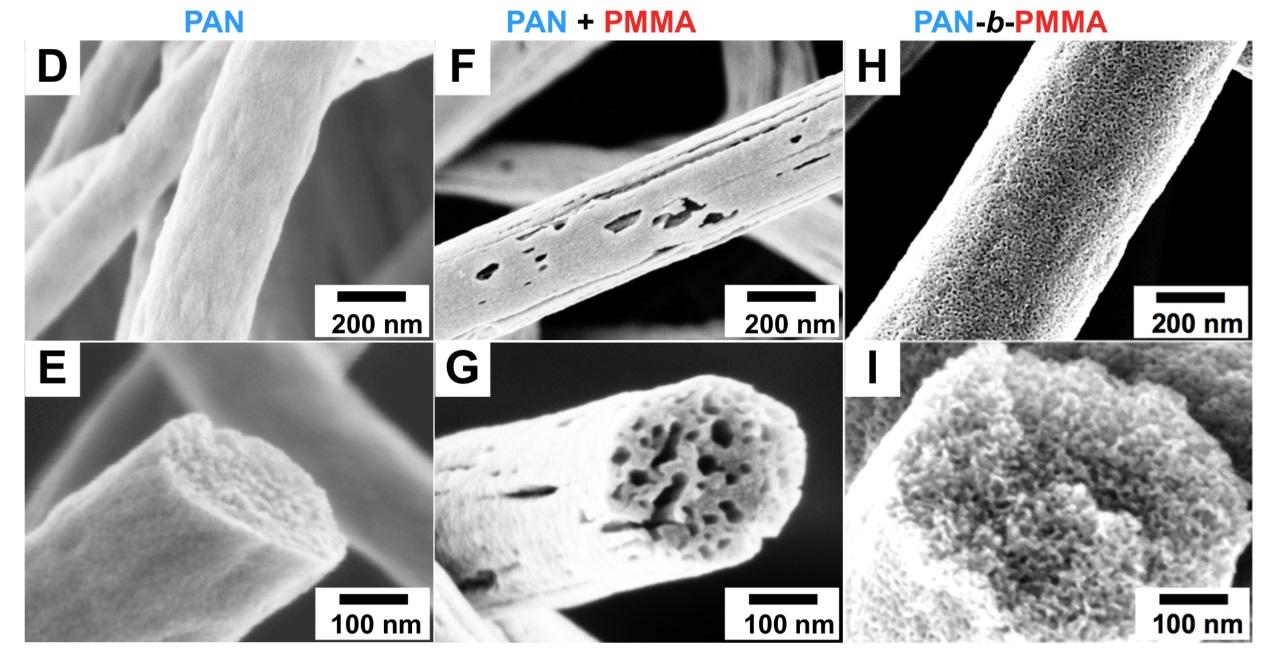

To do this, Liu used a multistep chemical process with two polymers called polyacrylonitrile (PAN) and poly(acrylonitrile-block-methyl methacrylate) (PMMA). PAN is well-known in the polymer chemistry field as a precursor compound for carbon fibers, while PMMA acts as a place-holding material that is later removed to create the pores.

In the past, chemists had typically mixed PAN and PMMA separately into a solution, which created porous carbon fibers with differently sized and spaced pores. But energy storage can be maximized with greater surface area, which occurs with smaller, uniform pores.

Liu came up with the new idea of bonding PAN and PMMA, creating what is known as a block copolymer. One half of the compound polymer is PAN and the other half is PMMA, and they're covalently bonded in the middle.

"This is the first time we utilize block copolymers to make carbon fibers and the first time to use block copolymer-based porous carbon fibers in energy storage," Liu said. "Often, we're only thinking from the process point-of-view, but here we're thinking from the materials design point-of-view."

After synthesizing the block copolymer in the lab, the viscous solution underwent three chemical processes to produce porous carbon fibers. The first step is electrospinning, a method that uses electric force to create fibrous strands and then harden the strands into a paper-like material. Next, Liu put the polymer through an oxidation heating process. In this step, the PAN and PMMA naturally separated and self-assembled into strands of PAN and uniformly scattered domains of PMMA.

In the final step, known as pyrolysis, Liu heated the polymer to an even higher temperature. This solidified PAN into carbon and removed the PMMA, leaving behind interconnected mesopores and micropores throughout the fiber.

Although this breakthrough improves an already high-performing engineering material, perhaps the greater breakthrough is the ability to use block copolymers to create uniform porous structures for energy storage possibilities.

"It opens the way we think about designing materials for energy storage," Liu said. "Now we can also start to think about functionality. We not only use (carbon fibers) as a structural material but also a functional material."

This story is adapted from material from Virginia Tech, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source. Article by Andrew Tie, Communications Coordinator, Virginia Tech Macromolecules Innovation Institute.