Delft Infra Composites, Breukelen, the Netherlands, was in charge of the structural engineering and production of the bridge. Lightweight Structures BV, of Delft, performed the structural design and analysis.

The advantages of using composites for this bridge included low structural weight, durability and low maintenance costs, plus design freedom.

Vacuum infusion

The structure of the bridge consists entirely of glass fibre reinforced polyester resin.

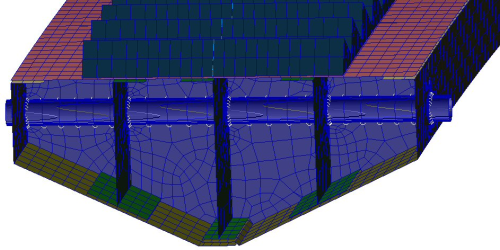

All composite parts were produced by vacuum infusion of polyester resin in non-crimp glass reinforcements.

Because of its dimensions, the bridge had to be produced in three separate sections which were subsequently joined together. The solid 15 mm laminate of each section was scarved back to just one layer over a 75 cm region. The sections were then joined to the adjusted sections by hand lay-up of three layers on the inside to ensure airtightness.

A similar approach was followed to join the internal longitudinal beams.

The bridge steps were produced separately by infusion and were subsequently bonded on to the deck to form the stairway.

Flexible design

The bridge was transported from its production site in Breukelen to the city of Nijmegen by inland barge and hoisted on to its supports in November 2013. In the following weeks, the railings were installed and the wear layer applied.

One of the requirements for this project was that the house boats should be able to pass underneath the bridge, even when water levels are high. In extreme water conditions, it should even be able to hoist the bridge temporarily from its supports. The bridge was therefore designed in such a way that it can be partly submerged in case of high water, without any damage to the structure.

The bridge was commissioned by the City of Nijmegen. The main contractor was Meerdink Bruggen and the architect Olaf Gipser.