The NASA Early Career Faculty Space Technology Research Grant program is designed to accelerate the development of innovative technologies in academia that address the needs if America’s space program as well as other government agencies and the commercial flight industry. Hansen’s grant is worth approximately US$579,000 spread over a period of three years.

Mechanical engineering assistant professor Chris Hansen’s project, entitled “Design and Fabrication of Aerospace-Grade Digital Composite Materials,” was identified by the space agency as a technology that could address the challenges in developing lightweight and multifunctional construction materials and structures for use in future science and human exploration missions.

Typical materials used on Earth to build structures, such as aluminum and steel, can be heavy and expensive to send into space.

Lightweight parts

“A kilogram of material can cost up to US$10,000 to fly into space due to the fuel requirements of the booster rocket,” said Hansen, who is the principal investigator for the project. “That’s why NASA is interested in funding research to develop very strong yet lightweight components or building blocks made of fiber-reinforced composite materials.”

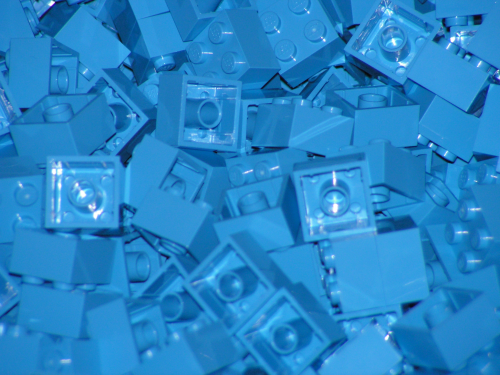

Hansen’s goal is to create a range of one-dimensional struts and two-dimensional plates components that can be assembled into a panel, sphere, cube, cylinder, boom, like space Lego, where interlocking pieces can be assembled in many ways to build a whole range of structures — from pressurized crew and laboratory modules to external trusses, nodes, solar arrays, antennas and other components like those found in the International Space Station.

“My research aims to conduct fundamental computational design and optimization of composite materials followed by experimentation in order to manufacture parts and test structures for aerospace applications,” he said.

Material choice

Hansen will use fabrication techniques such as pultrusion and 3D printing to make the composite materials. To create the struts, he will use either carbon or boron fibers.

"Carbon fibers are light and are excellent in handling tensional load, but not compression,” he said. “Boron fibers are slightly heavier and more expensive, but perform better with compression. Our choice of material will depend on the load applied to the structure.”

He adds: “Another unique aspect of this project is ‘reversibility.’ Anything constructed can be taken apart again and the pieces reused to make other new structures.”

“Once again, every kilogram you have to send up into space is very expensive so if you can harvest even half of the materials already in orbit and reuse them to form a new structure, that would be very helpful in terms of time, energy and cost. NASA is always interested in reducing the cost of launches, reusing materials and reducing a mission’s environmental impact for a more sustainable future.”