Formax has supplied more information about its new Innovation Centre, which it will be highlighting at the COMPOSITES EUROPE 2015 exhibition in Stuttgart, Germany on 22-24 September.

Led by Tom James, Director of Innovation, and now employing six staff, the department has recently restructured into three divisions focusing on polymer composites, automation, and ceramic composites.

‘The Innovation Centre will enable us to continue to support and grow our core business of composite reinforcements, and also allows us to expand beyond multiaxials,’ said Oliver Wessely, FORMAX's MD. ‘We see huge opportunities to exploit our technical textiles expertise in the area of preform manufacture and in numerous applications outside of the polymer composites industry.’

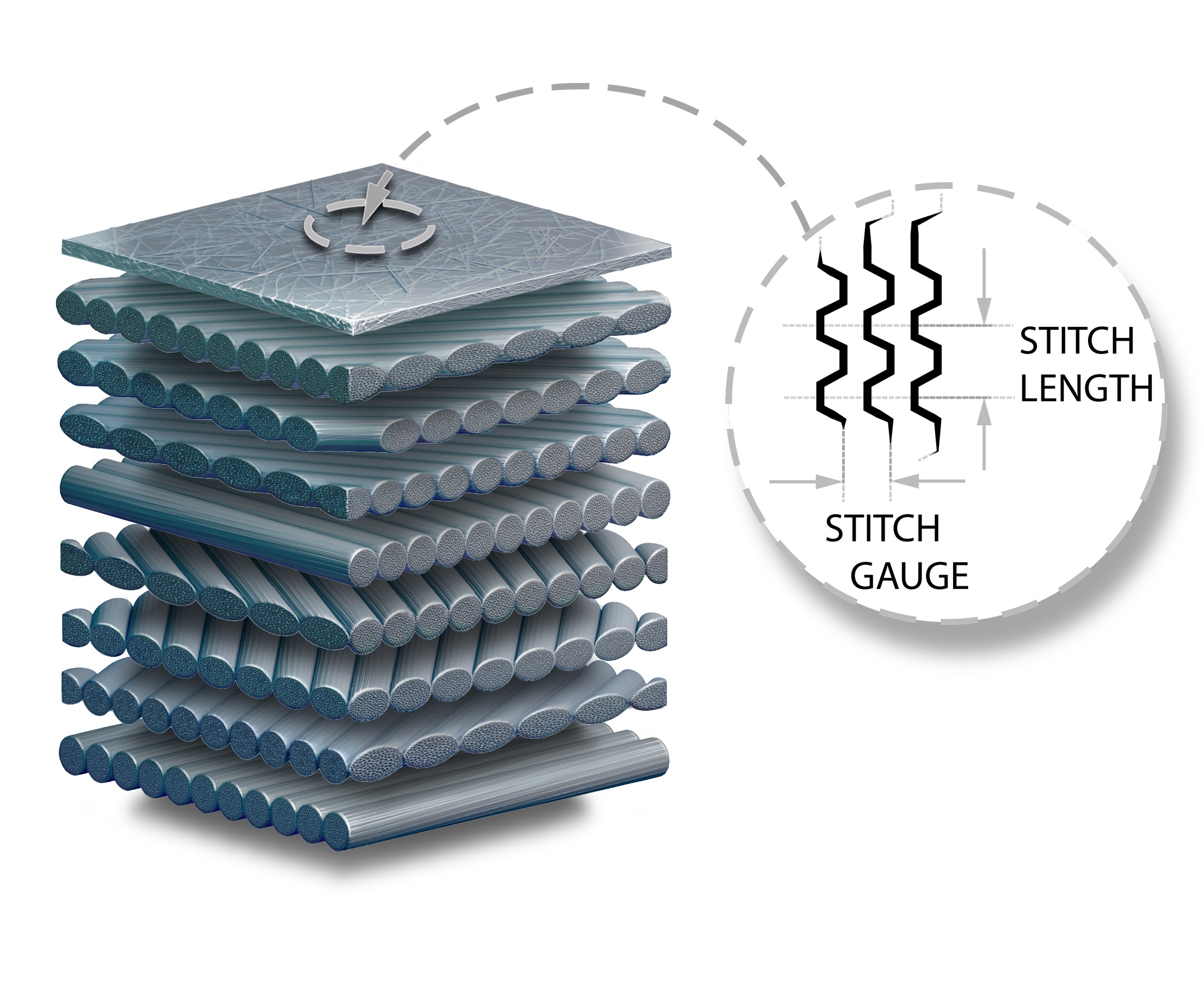

The polymer composites division will focus on improving multiaxial reinforcements for technically challenging applications. Areas of expertise will include testing and characterisation of fabric architecture, developing new products based on novel fabric architecture, and recycling.. Recent additions to the Innovation Centre include a modified ‘picture frame’ fixture and fabric bend testing equipment to aid in the study of fabric drape, and a fabric permeability test rig which can provide estimates of permeabilities at a given volume fraction for use in predicting resin fill time and dry spots.

The polymer composites division is led by Dimitris Karanatsis, who is currently enrolled on an Engineering Doctorate (EngD) program (Advanced CFRP Simulation for the Development of Fabric Architectures and Process Improvement), in collaboration with the University of Nottingham, UK.

Automotive specialties

Headed by mechanical engineering specialist Christopher Beard, the automation division's activities include fiber pre-processing (including tow spreading), fiber placement for automated net shape 2D preform manufacture, and automated 3D preform manufacture. Equipment includes a carbon fiber testing cell for use in characterisation of tow width, spreadability, filament orientation and filament breakage, and a robot for preforming studies. A fabric ply cutting and kitting service is also available.

The group is currently collaborating with a major automotive OEM, the Manufacturing Technology Centre Ltd in Coventry, the University of Sheffield, and the University of Nottingham, in the ALPA (Affordable Lightweighting through Pre-form Automation) project. With more than £2 million of funding from Innovate UK, this two-year program is aiming to develop technologies to significantly reduce the cost of using composites in vehicle structures, with a focus on reduced material wastage and automated preform manufacture for resin transfer moulded composite components.

The ceramic composites Division will pursue non-polymer applications for FORMAX's technical textiles. Current projects include the combination of novel, low cost ceramics with recycled short carbon fibers for use in high performance, low cost friction applications, and the carbon fiber reinforcement of concrete, bitumen and gypsum for civil engineering use. The Division is led by ceramics expert Dr Arthur Swarbrick, who recently joined FORMAX from the University of Loughborough.

This story is reprinted from material from Formax, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.