Around 18 months ago, McConaghy Boats of Sydney, Australia, which is best known for building high-performance, record-breaking racing yachts, was asked to assist explorer and film maker James Cameron and his engineering partner, Ron Allum, with the construction of the DEEPSEA CHALLENGER submersible. This submarine was intended to be capable of diving to the bottom of the Mariana Trench in the Western Pacific, 11 km (7 miles) down at the deepest part of the world's oceans.

|

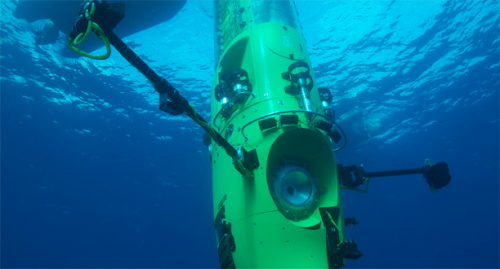

The 24 ft (7.3 m) tall, 11.8 ton DEEPSEA CHALLENGER has three main sections. The beam, the biggest single component, is made of a new kind of foam that provides both flotation and a strong structural core. The pilot sphere is slung below the beam, and below that an array of scientific gear stands ready to deploy at the bottom. About 70% of the submarine’s volume is taken up by syntactic foam. This is formed of millions of hollow glass microspheres suspended in an epoxy resin and is the only flotation material that can stand up to the incredible pressures in the deep ocean. The new type of syntactic foam developed for this project is called ISOFLOAT™ and has been patented. The sub descends because of more than 1000 lbs (450 kg) of steel weights held on to either side by electromagnets. To rise to the surface, the pilot flips a switch, the plates of steel will fall to the ocean floor, and the lighter-than-water foam will hurtle the sub skyward. The sub relies entirely on battery power. Source: www.deepseachallenge.com |

The pressures involved at these extreme depths meant any faults or voids in the materials or construction process could prove catastrophic. During a three-month period, McConaghy developed a solution for bonding more than 250 sections of the submersible's core buoyancy material – an extremely hard and high-strength composite foam structure innovated by Cameron's team called ISOFLOAT® and forming the 5.8 m main structure of the submersible. This beam had to be constructed to withstand 16 500 psi (114 MPa) of sea pressure, allowing the main beam to become massively compressed at its record-breaking depth at the base of the Mariana Trench, resulting in the submersible becoming 60 mm shorter than it is at sea-level.

McConaghy also worked closely with the Acheron Project, Cameron's and Allum's Sydney-based team, fabricating 95% of all composites in the project, including the main beam thruster units, doors, access panels and battery housings.