By Renewable Energy Focus staff

LM Wind Power has not released details on the actual size or materials for the wind turbine blade, but says it is focusing on aerodynamics, structural design, and production processes.

“Specifically developed material compounds will enable LM Wind Power to maximise strength and durability while producing an exceptionally light blade,” LM Wind Power and Alstom say.

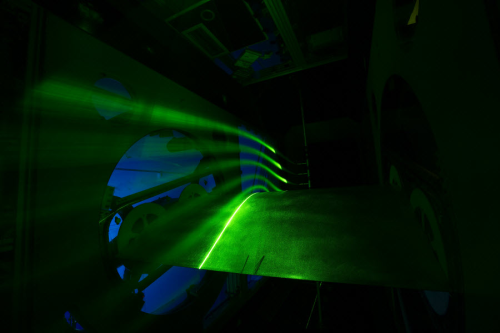

The wind turbine blade will be designed according to LM’s aerodynamic profiles based on its GloBlade, which is said to offer 4-5% higher annual energy production compared to ‘standard’ designs.

Prototypes will be produced at LM Wind Power’s factory in Lunderskov, Denmark, and will be ready for installation at Alstom prototype sites in Europe to start testing in the winter of 2011.

Alstom says its 6 MW permanent magnet direct drive offshore wind turbine has been optimised for the UK Crown Estate’s Round 3 and other North Sea Markets. Two prototypes will be installed in 2011 and 2012, a pre-series in 2013 and series production will start in 2014.

Alstom and EDF Energies Nouvelles will use the offshore wind turbine to jointly bid for projects under the 3 GW French offshore wind tender.