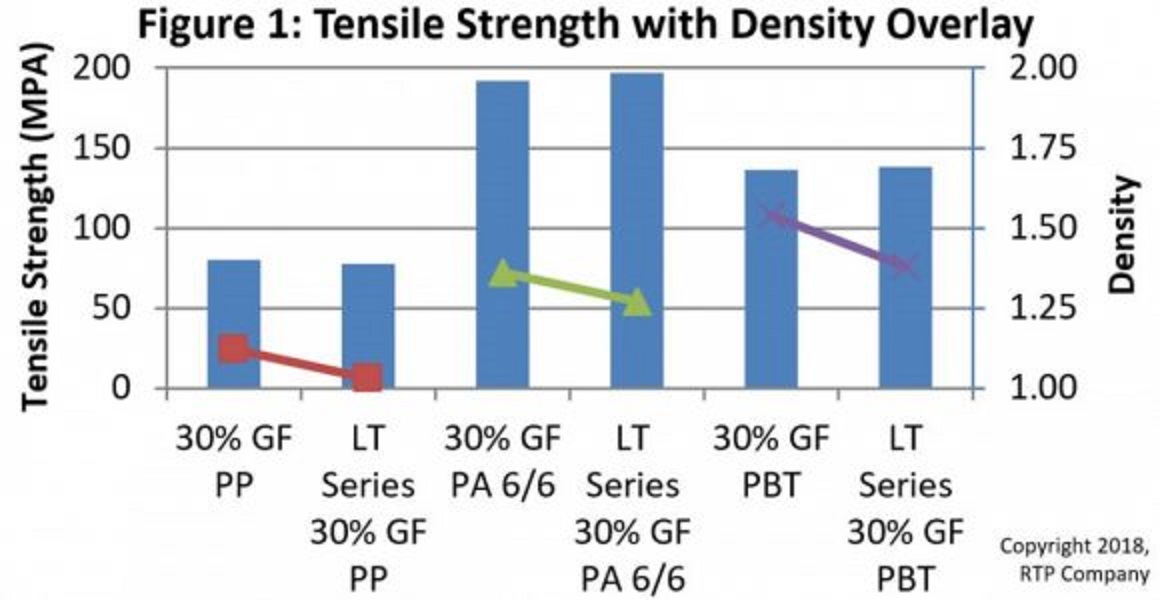

Thermoplastics specialist RTP has reportedly developed a series of thermoplastic compounds that weigh 5–10% less than typical filled compounds, but have equivalent mechanical properties and similar shrinkage values.

According to the company, the Light and Tough (LT) compounds can accomplish weight reductions in parts molded with glass fiber reinforcement without compromising performance or requiring modifications to existing tools. The density reduction is not dependent on wall thickness and since the compounds can be used as a drop-in solution with existing tooling, the switch from other materials can be more smooth and economical.

‘Our LT compounds can be drop-in replacements without the cost burden associated with other options to reduce weight,’ said Jason Kafader, structural product manager at RTP Company. ’LT Compounds from RTP Company are best used as lightweight alternatives when the goal is to minimize energy consumption or the amount of human effort required to use the part. This makes them an ideal material for handheld, battery-operated tools, sporting goods, handheld appliances, recreational vehicles, and other common markets for glass fiber reinforced compounds that will benefit from reductions in weight.’

This story uses material from RTP,with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.