The Learjet 85 features a carbon fibre composite fuselage and wing.

According to Bombardier, the composite structure will increase passenger comfort by allowing for the use of complex curves in the aircraft cross-section, thinner wall thickness to maximise cabin volume and optimised placement of windows and other cut-outs. The composite airframe also improves performance and minimises drag through smoother aerodynamics, and it requires less maintenance, is easier to repair and ensures extended service life.

The fuselage for FTV2 has also successfully completed its integrity inspection. Installation of the nose, bulkheads, floor, windshield and door surrounds are about to start. Once complete the main fuselage will be shipped with the aft fuselage to the final assembly line.

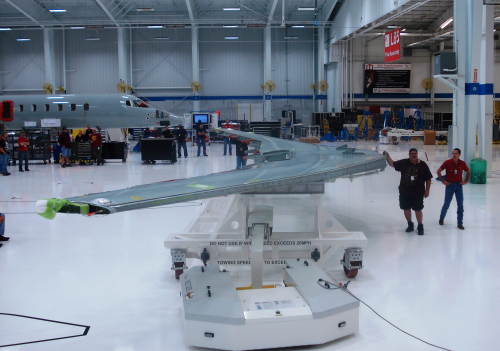

Wings for the complete aircraft static test article are expected to arrive from Querétaro, Mexico, by the end of November as preparations for static ground testing continue. (See Bombardier inaugurates Learjet 85 manufacturing facility in Mexico.)

The Learjet 85 is designed to carry eight passengers and is scheduled to enter service in 2013.

- Bombardier's CSeries aircraft, designed for the single-aisle 100- to 149-seat commercial aircraft market, is also scheduled to enter service in 2013. It also features composite wings. (See Bombardier throws down the gauntlet with CSeries airliner.)