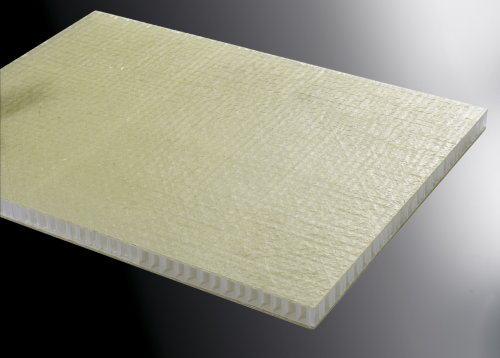

ROVIpan™ is reported to meet the wind energy market’s requirements for low weight, high strength and ecologically designed materials. With ROVIpan, nidaplast aims to make infusion easier – and at a reduced cost. This new product combines two materials: a polypropylene honeycomb core (nidaplast® 8RI) and a nonwoven polyester surface, together with glass-fibre skins with integrated flow medium in the form of Chomarat’s ROVIflow™.

Used as structural core material, nidaplast 8RI honeycombs are said to be more cost-effective and environmentally friendly than one-piece-moulded structures, by using smaller amounts of glass fibre and resin. With excellent mechanical and acoustic properties, nidaplast 8RI is reported to be an ideal core material for the wind energy market. The cell geometry of the polypropylene honeycomb structure also offers good vibration damping and acoustic insulation.

Suitable for manufacturing large sandwich parts in 5-40 mm thickness, ready to use and easy to handle, ROVIpan reduces the requirement for manual labour which also decreases the moulding cycle. By optimising materials with lower resin consumption for a better quality composite, higher glass content and improved surface finish, nidaplast is confident that this will enable further cost reductions to industrial markets. The material also meets environmental standards by reducing volatile organic compound (VOC) emissions.