The Biotex products, a brand of Composites Evolution, Chesterfield, UK, include commingled flax/polypropylene (PP), commingled flax/polylactic acid (PLA), and flax yarns, fabrics and preconsolidated sheets which could be processed in a variety of composite products.

Natural fibres are already being used to reinforce plastics, for example in injection moulded or press moulded interior parts for the automotive industry, but the fibres are generally short and randomly oriented, giving relatively low mechanical properties. The Biotex materials are based on twistless yarns with long, aligned fibres to exploit the inherent mechanical properties of flax in load-bearing applications, with the added advantage of having a lower weight than conventional reinforcements such as glass fibres.

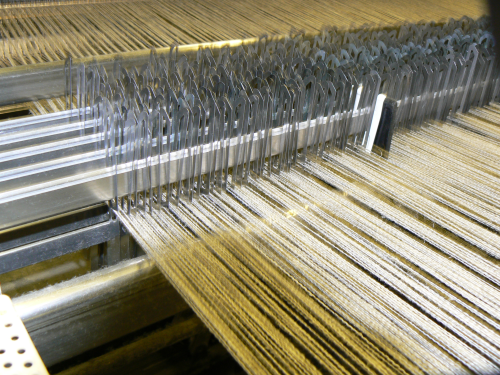

The natural fibres in Biotex yarns are highly aligned to give up to 50% better fibre efficiency over conventional twisted yarns. The twistless yarns are also said to allow fast wet-out and impregnation, giving improved fibre/matrix interaction and better performance.

The Biotex flax/PP and Biotex flax/PLA commingled materials include an intimate blend of the reinforcement fibre and matrix polymer for easy processing by vacuum consolidation or press moulding.

Flax fibres are renewable and have a low environmental impact during processing. The matrix in commingled Biotex flax/PLA is also derived from crops, giving a 100% renewable material that can also be recycled or composted at the end of its life.

”The development and use of renewable materials is becoming increasingly important in today’s environmentally conscious society," says Dr Brendon Weager, Technical Manager for Biotex. "This new family of high-performance biomaterials is a major step towards harnessing the true potential of natural fibres and biopolymers, for the first time making high-performance biomaterials a reality.”

The Biotex product launch follows the results of a project co-funded by the UK Technology Strategy Board's Collaborative Research and Development programme, following an open competition.