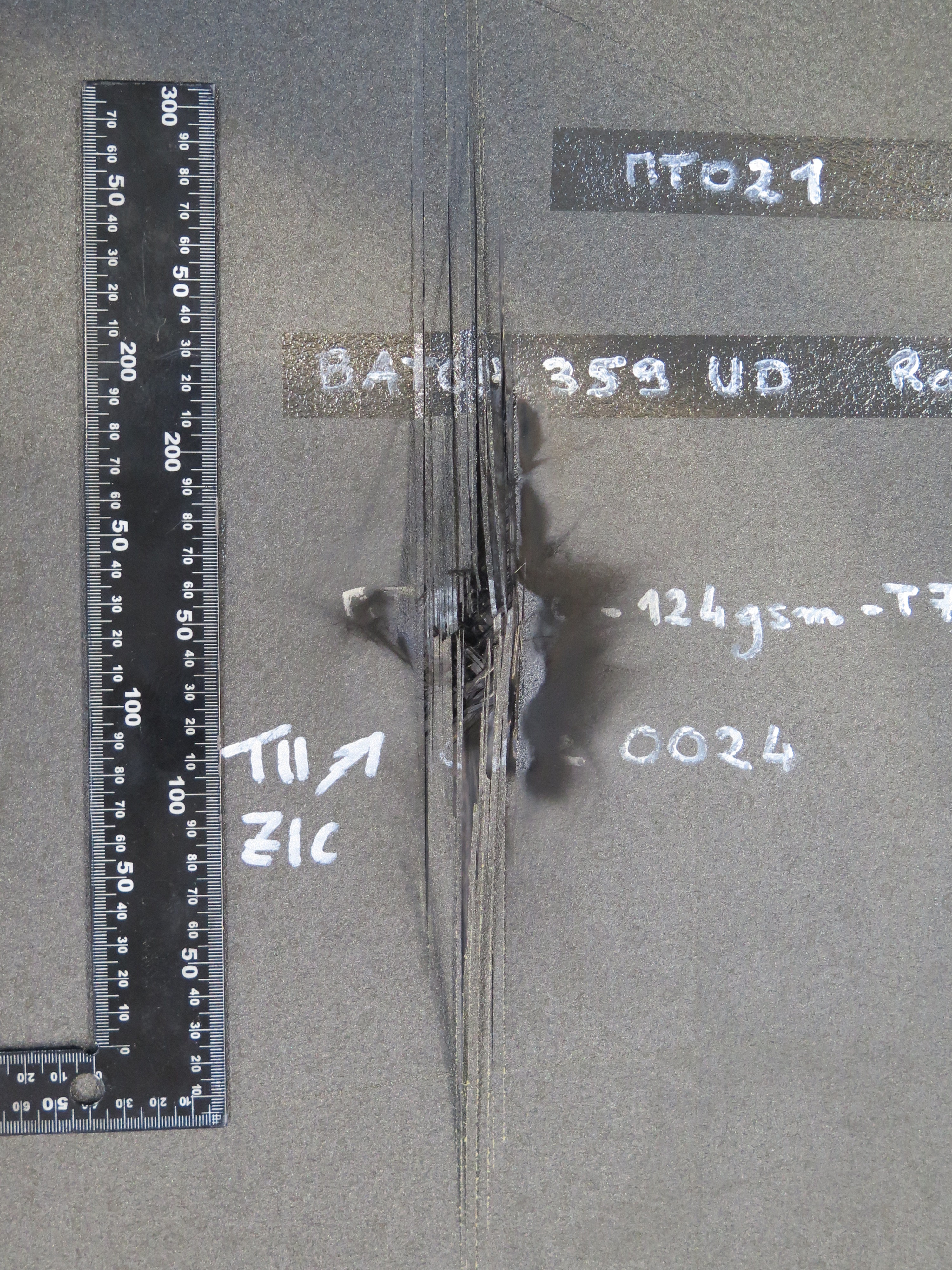

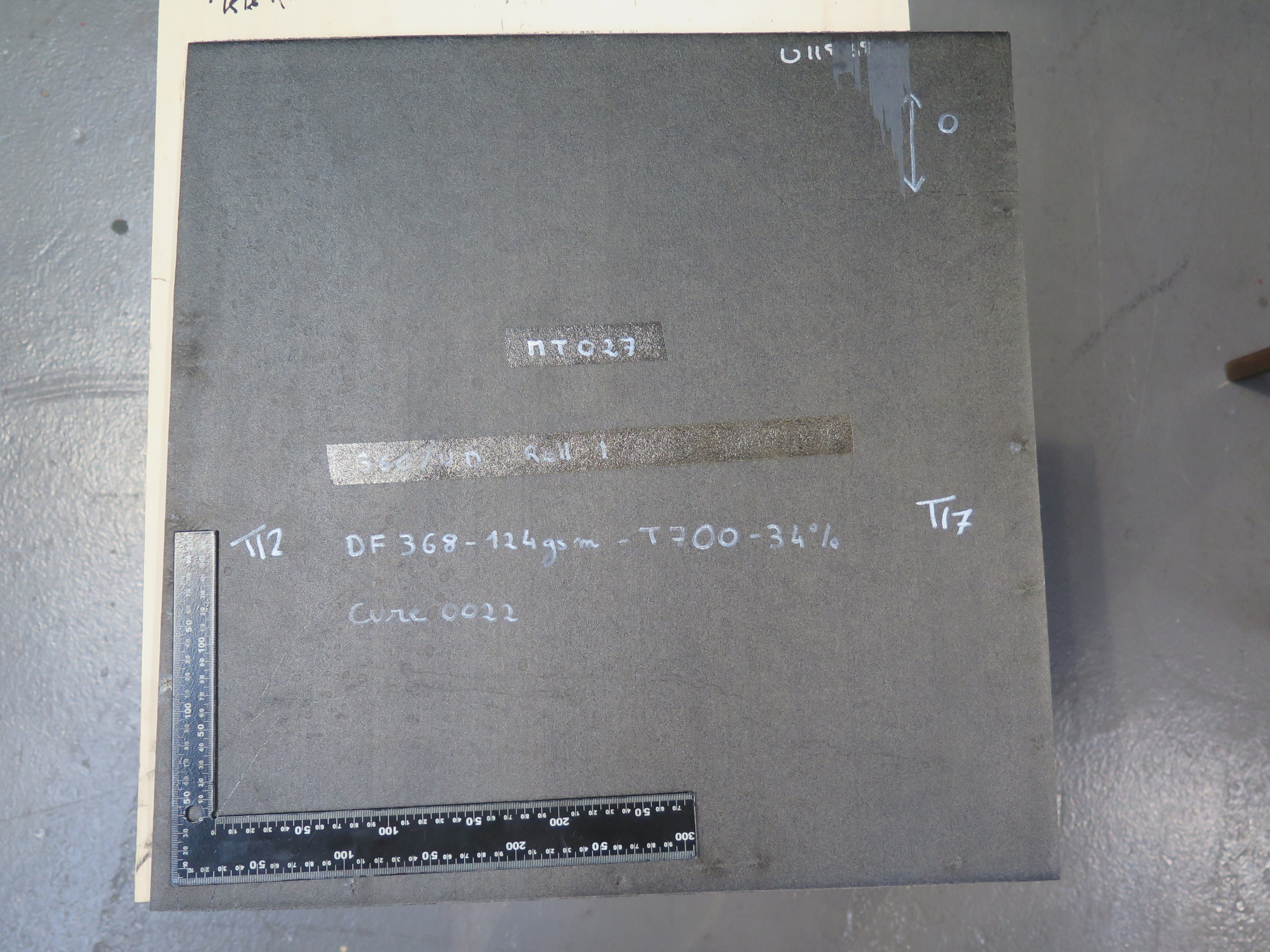

Haydale Composite Solutions has developed electrically-conductive carbon fiber-reinforced composite materials featuring graphene powder with improved resistance to damage from a severe lightning-strike event.

Carbon fiber-reinforced composite materials, as used in many aerospace structures and components, are vulnerable to damage from lightning strikes. However, the addition of functionalised nano materials to epoxy resin through the use of Haydale’s patented plasma functionalisation process, HDPlas, could significantly improve the electrical conductivity of the epoxy resin which allows the laminate to dissipate the energy of the lightning strike throughout the structure.

The mechanical properties of the modified material have been evaluated and it has been shown that the properties are maintained or improved by the addition of specific nano particulates.

This work has been conducted as part of the NATEP-supported GraCELS Project, a collaborative research project involving Haydale Composite Solutions, Airbus UK, BAE Systems, Cobham Technical Services and SHD Composites. The graphene-modified material has been used to manufacture a 4 m long aileron from a design from Airbus for its Eco-Flyer aircraft. The carbob fibre reinforced plastic (CFRP) used in the aileron manufacture is shallow-angled, thin ply construction supplied by Chomarat and features other composite-specific design aspects.

Renewable energy

‘The development of a composite material with significantly improved lightning-strike performance while maintaining or even improving the mechanical performance will allow aircraft manufacturers to produce vulnerable parts that are lighter and cheaper to produce than current methods allow without compromising flight safety,’ said Gerry Boyce, MD of Haydale.

According to the company, the the electrically-conductive carbon fiber prepregs created in the GraCELS project could also be suitable for applications where metallised coatings or meshes are currently incorporated into CFRP such as electronic enclosures requiring EMC or RF shielding, for masts and large turbine blades in the renewables energy sector and in applications where static discharge may be a critical factor in materials selection amongst others.

This story uses material from Haydale,with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.