OCSiAl says that its TUBALL graphene nanotubes have been used to reinforce and improve grain pipes and other system elements for the cleaning, drying, storage and processing of grain.

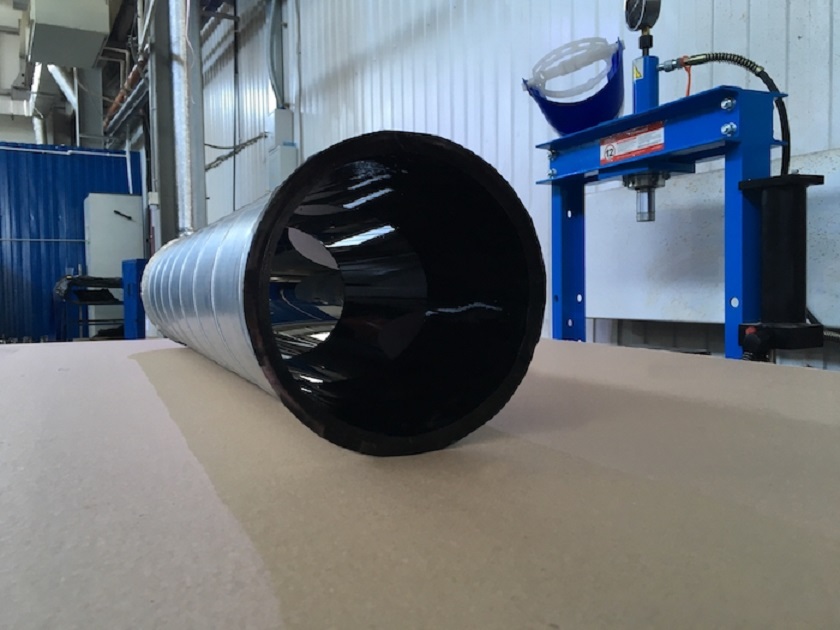

The company says that the material is better than lining the pipes with polyethylene attached to the metal with rivets, which can increase the cost of the pipe and its weight. In addition, at the time of transportation, accumulation of static electricity occurs, which regularly causes blockages and can lead to ignition of grain dust, OCSiAl added. TUBALL is made of an antistatic polyurethane lining reinforced with graphene nanotubes applied as a layer 3–10 mm thick onto the inner surface of the pipe by hot casting, which provides strong adhesion and a stable level of resistivity of 10^5 Ω·cm. According to the company, the lining can increase the service life of the grain pipeline since the coating loss by weight is 0.05% after 100,000 tonnes of grain passing, which allows these pipes to be used for several seasons without replacement.

This story uses material from OCSiAl, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.