GKN Aerospace will also make use of VISTAGY's services, including process consulting, best practices development and customised training.

GKN Aerospace has used VISTAGY's FiberSIM composites engineering software for more than eight years in the design of various complex composite parts, including the winglets on the Boeing 767, the leading edge for the Airbus A380 wings, and the wing spars for the Airbus A400M. The adoption of SyncroFIT software for the Bombardier CSeries winglet extends the ongoing partnership between the two companies.

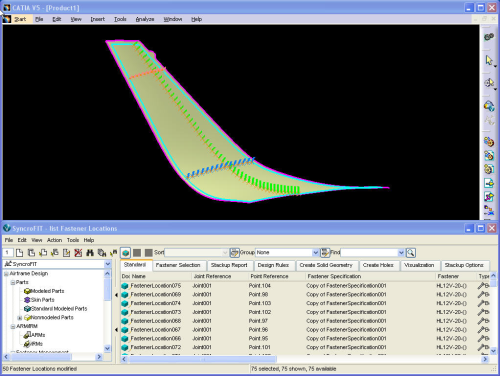

Engineers will use SyncroFIT to define fasteners early-on in order to provide procurement with precise and up-to-date bills of materials (BOMs). GKN Aerospace will also use SyncroFIT to manage the interactions of composite details within assemblies so that its engineers can validate that fastener design rules have been met and that the ripple effect of changes during skin thickness updates are propagated throughout the assembly.

“Defining holes and fasteners is a critical issue for developing composite aircraft because the variation in skin thickness drives the need for a wide array of fasteners and adds complexity to the design,” explains Justin Elliott, GKN Aerospace’s chief engineer on the CSeries aircraft winglet programme. “SyncroFIT unravels this complexity by enabling us to easily author and capture complete digital representations of airframe assemblies and share critical design and manufacturing detail more efficiently. VISTAGY’s software and services will enable us to take an integrated approach to design and airframe assembly that will help us meet our goals.”

- GKN's contract for the design and manufacture of the CSeries composite winglet could be worth more than US$100 million. First winglet deliveries will take place in early 2011; the CSeries will go into service in 2013. GKN Aerospace will supplying the winglet from its composites centre on the Isle of Wight, UK. The contract was awarded by Bombardier Aerospace, Belfast, Northern Ireland, which is responsible for the design and manufacture of the composite wings for the CSeries aircraft family.