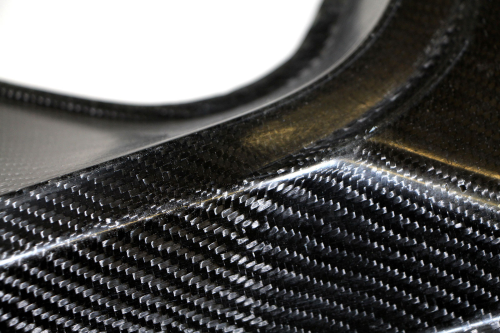

According to the researchers, variants derived from hemp, flax, cotton and wood are about as affordable as glass fibers, and have a lower density than the pendants made of glass or carbon. Moreover, when incinerated at the end of their life cycle, the natural fibers produce additional energy without leaving residues. However, their durability and stability don´t reach that of carbon fibers. Therefore, depending on the application, the scientists are looking into combining carbon with various bio-based textile fibers. The fibers typically exist as fabrics that are placed on each other accordingly and are embedded by the plastic matrix.

“We use carbon fibers in those areas where the part undergoes intense mechanical stress; in other areas, it’s natural fibers,” said Prof. Dr.-Ing. Hans-Josef Endres, head of the Application Center for Wood Fiber Research. “This way, we can leverage the strengths of the respective fibers and get rid of the disadvantages to a great extent.” As a result, the parts are more cost-effective, have an improved degree of durability and acoustic properties and are substantially more ecological than pure carbon components, he says.

Surface treatment

Typically, engineers treat the surface of the natural fibers so that they can be run more easily through the textile equipment, and can be processed as well as possible into fabrics. While this is important for textile production, it is usually counterproductive if composite materials have to be processed. “This is why, from a materials engineering perspective, we optimize the surfaces of the fibers,” said Endres. Specialized surface treatments or coatings are intended to ensure that the fibers can be combined and interact in the best possible way with the matrix or the plastic mass.

“By ensuring that the fibers bond to the matrix optimally, we can increase the durability of the materials by up to 50%,” Endres claimed.

Disposal potential

The Fraunhofer researchers are also studying how the processing processes for these new materials can be implemented on an industrial scale and how the hybrid materials can be properly disposed of.