Formax, a manufacturer of carbon fiber and speciality composite reinforcements, is building an Innovation Centre at the company's headquarters in Leicester, UK.

Scheduled to open in September, the facility will house a new laboratory, testing and simulation area, and prototyping center, all intended to help improve reinforcements for individual applications. It will focus on fabric architecture development for polymer and ceramic composites, fabric and composite characterisation and process simulation.

Formax says tha it will continue to invest in improving its custom multiaxial reinforcements for companies in the automotive, marine, wind energy, sports and industrial markets.

‘Increasingly our role has expanded to include an advisory service,’ said Tom James, director of innovation at Formax. ‘In recent years there has also been an increase in demand for us to perform the additional role of simulation support, led by automotive customers and their need to simulate process and performance during the early stages of product design.’

Material permeability

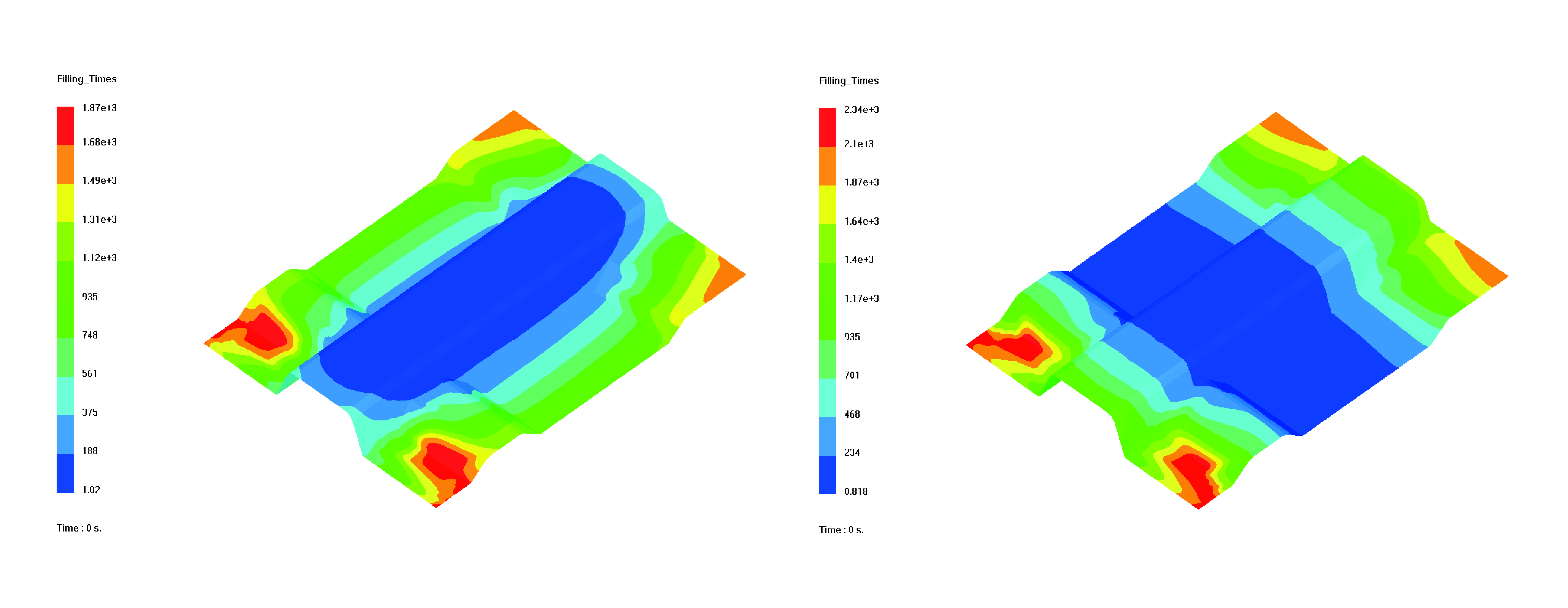

To improve the development of optimised fabrics for resin transfer moulding (RTM) and infusion processes, the Innovation Department, working with the University of Nottingham, UK, recently commissioned a permeability measurement rig. Knowledge of the permeability of fiber reinforcements allows for better design of injection tooling and process flow, as well as aiding the development of impregnation processes for structural parts, the company says.

The new rig calculates the permeability of preform stacks using a low-viscosity silicon oil. The permeability rig provides estimates for permeabilities at a given volume fraction. These values can be used with analytical hand-calculation methods or flow simulation software to provide predictions of fill time and dry spots.

This story is reprinted from material from Formax, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.