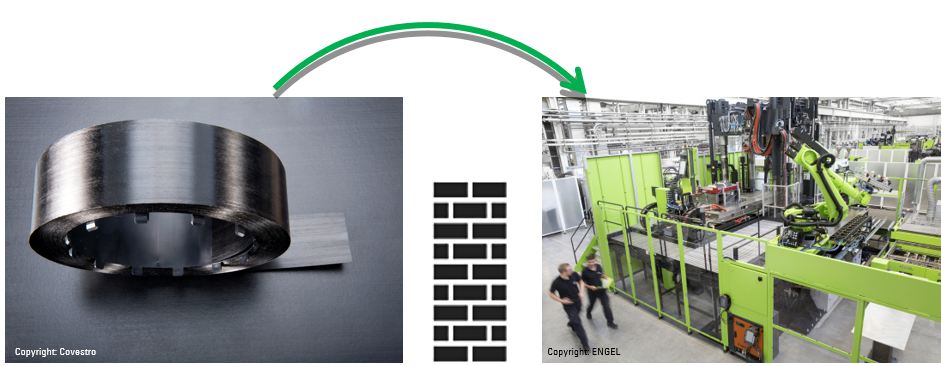

German engineering consultants AZL and the Institute of Plastics Processing have been working with companies on how thermoplastic tapes can be used more in the production of injection molded parts.

As local reinforcements, thermoplastic tapes can improve product properties of injection molded parts and save costs due to an efficient use of materials, the organizations say. They have increased stiffness and strength, higher surface hardness and improved optics which can help improve conventional injection molded parts. However, the majority of injection molders use thermoplastic tapes and their potential only occasionally, AZL and the Institute say.

Engineers at RWTH Aachen University are working on an overview of injection molding applications that are particularly suitable for being optimized with the use of thermoplastic tapes. The focus is particularly on conventional injection molded parts and not exclusively on typical lightweight applications, it says.

More information can be found here (pdf).

This story is reprinted from material from AZL, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.