Evonik says that the company’s focus at JEC World will be automated production with the aim of improving efficiency.

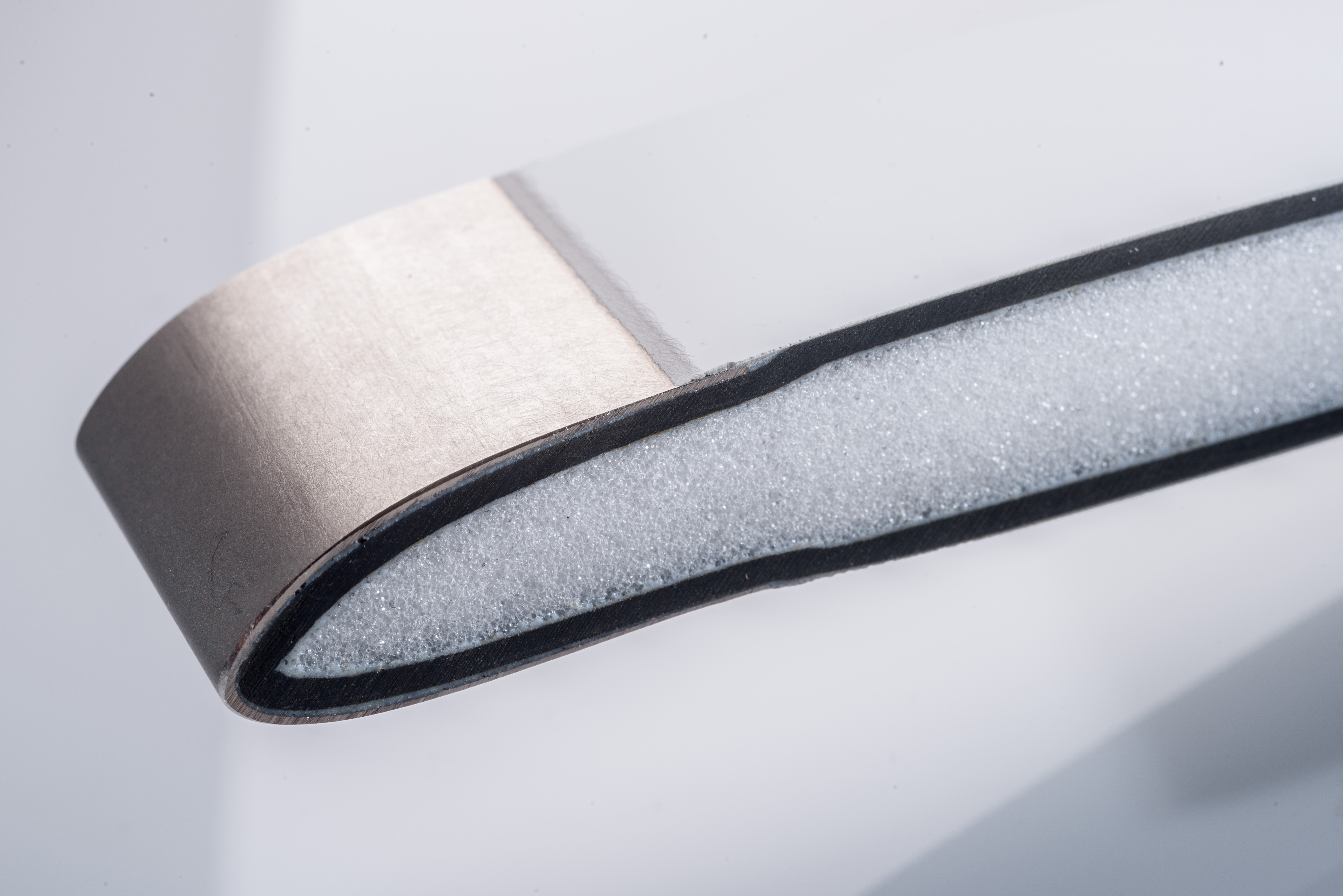

The company will feature a joint study by Evonik Industries, Composite Technology Center GmbH and Deutsche Zentrum für Luft und Raumfahrt eV, on the use of rigid foam material in automated production. As well as this it will display a partial composite helicopter main rotor blade produced by Van Horn Aviation (USA) for the 206B JetRanger helicopter. The blade was fabricated with a Rohacell 71HERO foam core and Toray carbon fiber, then autoclave co-cured. ‘And this year, Evonik is significantly expanding its Rohacell facility in Mobile and is also investing in a new, modern production facility in Darmstadt which is scheduled to come on line by the end of 2021,’ said Dr Kai-Martin Krüger, head of Evonik's performance foams product line.

This story uses material from Evonik, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.