Each joint-less ebablock® EP 138 block is custom cast to close to contour tolerances and can be delivered to a customer’s premises anywhere in Europe within seven days from receipt of order.

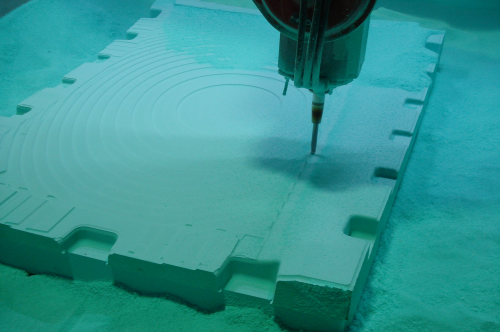

Ebalta maintains that the ‘cast to size’ approach has significant advantages over the traditional method of bonding together tooling boards to create the ‘raw’ tool shapes. With the ebablock EP 138 tooling blocks no post processing is required, milling times are considerably shorter and waste is reduced.

The blocks have good dimensional stability up to 140°C. This together with a coefficient of linear expansion of ~35 x 10-6K-1 means that the blocks are suitable for the manufacture of prepreg tools for autoclave applications. Although the tooling blocks have applications throughout the composites industry, Ebalta expects them to be of particular interest to producers of components for the race car and aerospace markets.

To meet the expected demand for this new range and its existing polyurethane cast to size blocks, Ebalta has established, a purpose-built 2000 m2 facility at its headquarters in Rothenberg, Germany, that is exclusively for the production of the ebablock range.

Ebalta specialises in the manufacture and supply of composite tooling materials and tooling boards based on polyurethane and epoxy resin systems.