The new Fiberspar 165 000 ft2 centre will increase total capacity by over 50% and help reduce lead time and transportation costs to serve the Bakken, Niobrara, and the overall oil and gas market in the Rockies region.

According to Peter Quigley, Fiberspar CEO, this expansion into the Rockies is a reflection of continued industry acceptance of Fiberspar LinePipe spoolable composite pipe as a lower installed and operating cost alternative to welded steel pipelines for in field gathering and injection applications.

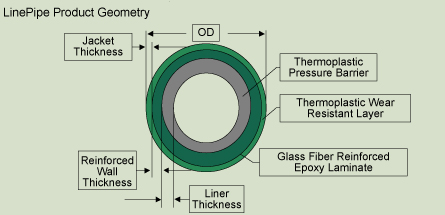

LinePipe consists of an inner thermoplastic pressure barrier that is reinforced by high-strength glass fibres embedded in an epoxy matrix. It is available with high-density polyethylene or high temperature polyethylene pressure barriers with temperature ratings to 140°F and 180°F respectively.

Fiberspar reports that in addition to total installed costs savings of over 20% compared to welded steel, LinePipe does not corrode and installs in half the time, requiring fewer people and less equipment.