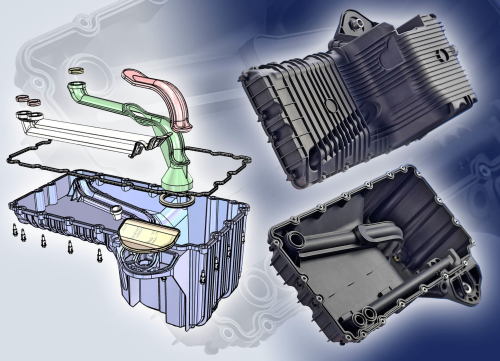

A key element of the design is the integration of components that are part of the oil-circulation system. This approach not only results in a component that is 40% lighter than its aluminium equivalent but has also led to reductions in manufacturing and assembly costs. The new design from ElringKlinger involves the single-stage injection moulding of not just the pan (which measures approximately 550 x 400 mm x 300 mm) but also sections of the pipeline connected to the sump and the fastening flanges for the pressure pipelines to and from the oil filter. The oil pan is manufactured from DuPont Zytel® 70G35 HSLRA4 – a polyamide (PA) 66 thermoplastic resin that is reinforced with 35% glass fibres by weight. This material combination allows ElringKlinger to produce an oil pan that is both very stiff while continuing to offer high impact resistance at temperatures up to 150°C. Other features of the resin system include a high resistance to lubricants, road salts and other media commonly present in and around vehicles. “Our selection of a particularly high melt flow grade of Zytel meant that we were able to manage the long flow distances at a comparably low injection pressure and despite some very low wall thicknesses,” says Ralf Franz, development engineer at ElringKlinger. “This, in turn, reduces cycle times, helps preserve the tool and reduces energy costs.” “The low warp characteristics of the material are a decisive benefit for this application, as it facilitates a durable and reliable seal along the circumference of the oil pan,” he adds. “We had to design the new polymer oil pan in such a way that its connection to the engine was consistent with the metal construction previously used. We were thereby presented with relatively large distances between the connection points. Due to the high stiffness of the material, we managed to limit deformation under load to the required rate thereby ensuring a constant surface pressure across the whole perimeter.” When car oil pans made of thermoplastic polymers were first launched, the initial priority was the replacement of considerably heavier components made of die-cast or sheet metal. Today, with the additional design freedom provided by reinforced thermoplastics automotive parts, manufacturers such as ElringKlinger are looking for increased functionality. ElringKlinger specialises in the production of cylinder head- and purpose-made seals, polymer housing modules and shielding systems for engines, transmissions and exhaust lines. It has 27 sites across Europe, America, Asia and Africa and employs over 4100 people.