As a result of this partnership, DSM plans to relocate a team of experts from its Ludwigshafen unit into new offices at a technology park in Karlsruhe, close to the ICT. Alongside this DSM Composite Resins will concentrate R&D capabilities in the company’s main R&D centre in Zwolle, The Netherlands, and plans to stop operations at the Ludwigshafen site by end of 2009.

“We are very excited, that DSM has decided to form this partnership with us, as we are proud to be able to work with the number one in the composite resins industry,” says Professor Frank Henning, Deputy Director of the Fraunhofer ICT.

Henning is also head of the newly-founded Karlsruhe Innovation Cluster, KITe hyLITE – Technologies for Hybrid Lightweight Construction, and the Competence Centre for Lightweight Automotive Construction. Research services range from conceptual design through material, process and product development to the manufacture of prototypes.

“With Fraunhofer ICT’s proficiency and leading position in research and development in composites we have found the ideal partner for joint applications and processes in automotive and other composite markets,” says Dr Michael Effing, President of DSM Composite Resins.

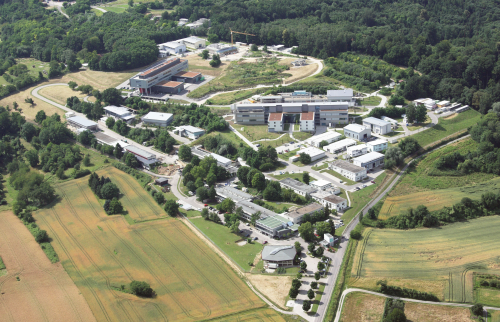

The Fraunhofer Institute for Chemical Technology (ICT) belongs to the Fraunhofer Society. In Pfinztal ICT employs around 450 people.

DSM Composite Resins is part of DSM Resins, a group within the Performance Materials cluster of DSM.