The part, which supports the engine with the aid of the engine mounts, is moulded from BASF's Ultramid® A3WG10 CR, a glass fibre reinforced (50 wt%) polyamide 66 (PA 66) which is optimised for high mechanical loads.

Joma-Polytec GmbH in Bodelshausen, Germany, designed the injection mould and produced the composite engine support.

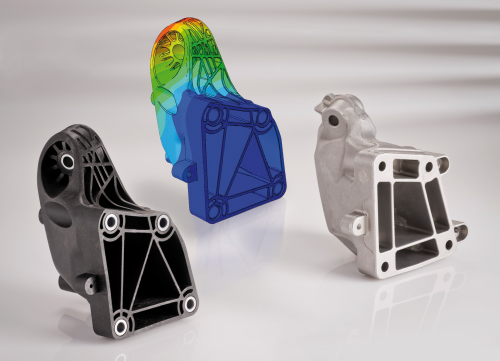

Better than aluminium

Engine supports are subject to a permanent load – the engine's weight – and must also absorb the entire engine torque. To date, they have always been made from aluminium, reports BASF.

The good acoustic characteristics of the Ultramid engine support are the main advantages over its aluminium counterpart. Thanks to its damping behaviour, the new engine support contributes to a more balanced sound.

Another benefit is that the heat conduction of the thermoplastic is considerably less than that of aluminium. As a consequence, the composite engine support provides better protection from the engine's heat for the natural rubber engine mounts connected to it, increasing their service life.

The plastic part also weighs more than 30% less than the aluminium version.

The tests that the plastic part must pass include the so-called repair crash, which replicates smaller crashes, and the massive offset crash (offset head-on crash). In the first case, the support must remain undamaged; in the second case, it must fail quickly and in a specific manner to prevent the engine entering the passenger compartment.