Internal damage in fibre reinforced composites is difficult to detect and nearly impossible to repair by conventional methods, note the reseachers at the university's Beckman Institute (Autonomous Materials Systems Group). A small, internal crack can quickly develop into irreversible damage from delamination.

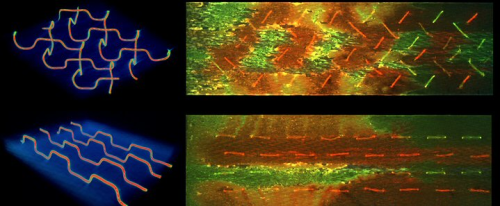

The research team, led by professors Nancy Sottos, Scott White and Jeff Moore, have created 3D vascular networks (patterns of microchannels filled with 'healing' chemistries) that thread through the composite. When damage occurs, the networks within the material break apart and allow healing agents to mix and polymerise, autonomously healing the material, over multiple cycles.

Repeated healing

| This is the first demonstration of repeated healing in a fibre-reinforced composite system. |

| Scott White |

“Self-healing has been done before in polymers with different techniques and networks, but they couldn’t be translated to fibre-reinforced composites", says Scott White, aerospace engineering professor. "The missing link was the development of the vascularisation technique.”

The vasculature within the system integrates two networks that are isolated from one other. Two liquid healing agents (an epoxy resin and hardener) are contained in two different microchannel networks.

“When a fracture occurs, this ruptures the separate networks of healing agents, automatically releasing them into the crack plane – akin to a bleeding cut,” explains Jason Patrick, a PhD candidate in civil engineering.

“As they come into contact with one another in situ, or within the material, they polymerise to essentially form a structural glue in the damage zone. We tested this over multiple cycles and all cracks healed successfully at nearly 100% efficiency.”

“Additionally, creating the vasculature integrates seamlessly with typical manufacturing processes of polymer composites, making it a strong candidate for commercial use,” notes Nancy Sottos, materials science and engineering professor.

The researchers stitched in a sort of 'fishing line,' made from a bio-friendly polymer and coined 'sacrificial fibre,' within the composite. Once the composite was fabricated, the entire system was heated to melt and evaporate the sacrificial fibres, leaving behind hollow microchannels, which became the vasculature for the self-healing system.

Further information

These results were detailed in a paper titled Continuous self-healing life cycle in vascularized structural composites, published in the journal Advanced Materials.

This work was supported by the Air Force Office of Scientific Research, the Department of Homeland Security Center of Excellence for Explosives Detection, Mitigation, and Response, and the Army Research Laboratory.