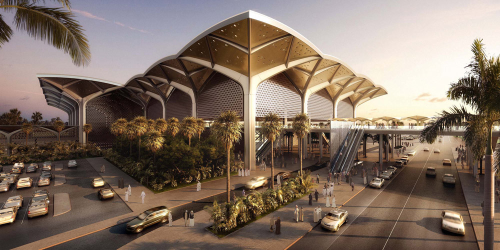

The Haramain High Speed Rail project runs between the cities of Makkah and Medinah, with additional stations at Jeddah and the King Abdullah Economic City.

The stations, designed by a joint venture of Fosters + Partners and Buro Happold, have a modular arrangement, with a steel main structure supporting structural fibre reinforced plastic (FRP) roof panels that have panel spans of up to 9 m. In total there is over 160,000 m2 of FRP panels across the four stations.

Gurit and Premier Composite Technologies (PCT) worked with the design team to develop the composites roof concept. The lightweight and inherent insulation achieved with fibre reinforced plastic (FRP) sandwich panels, combined with the accuracy obtained by moulding panels using CNC machined tooling and the durability of composites offered significant advantages to the project.

The large panel spans made feasible by the use of sandwich construction also enable rapid installation of the roof without requiring any secondary structure. The modular design of the station meant that there was a large degree of repetition of panels which allowed efficient use of moulds.

Roof manufacture

The detailed design and fabrication of the roof of Medinah station was awarded to PCT by main contractor Yapi Markazi. Gurit has carried out the structural analysis and optimisation of the roof panels for this station, which has a surface area of around 28,000 m2 (300,000 ft2).

The weight of the composites is approximately 720 tonnes, which makes the station roof one of the most extensive uses of advanced composites in the architectural industry.

Materials chosen for the laminating of the panels were Gurit's Ampreg 21FR, a fire retardant epoxy laminating system, Spabond 340LV structural adhesive, and G-PET™ 75FR and G-PET™ LITE™, a lightweight, fire retardant, closed cell structural foam core.

Lamination of the panels is now well underway at PCT premises in female moulds, and a trial installation of part of the roof has been erected and tested. The correlation between the deflections of the full scale test and those predicted by the FE model developed by Gurit engineers was very good, with a difference of less than 2% between the two.

PCT will install the roof panels during 2013 once the steel supporting structure has been completed in Medinah.

- Gurit will be exhibiting for the first time at the AIA (The American Institute of Architects) Convention in Denver, Colorado, USA, on 20-22 June 2013, showcasing composite solutions for architectural applications.