“Currently (most) new homeowners will install a roof and then, as a secondary process, will have another company come in and install a limited number of standard heavy glass fronted solar panels on top of the roof," explains The Specialty Group's CEO Daniel Leipnik.

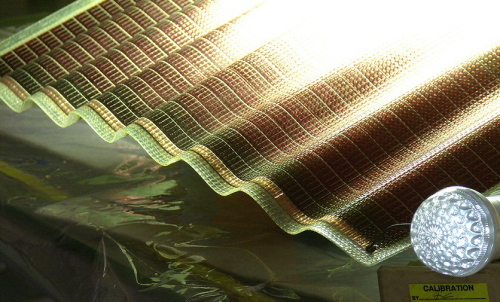

"Our intended technology is a building integrated photovoltaic product, known as BIPV, where the roofing material itself has solar cells embedded into it. This means that a 'solar roof' can be installed on a house or a building as a one step process allowing for far more coverage of photovoltaic material, greater overall solar energy generation and far less installation cost.”

Essentially this concept will enable roofers to take large corrugated panels off the ground or a truck, lift them up onto a roof, screw them into the rafters like standard corrugated roofing materials and then connect the wires from each panel into an inverter so that the majority of the building’s roof is one big solar panel.

The roofing material involves the use of UV curable glass fibre prepreg manufactured by The Specialty Group's composite division, Australian Composites.

“We are planning to create a world first application for high volume, low cost, light weight solar roofing sheeting for a global market place that can be produced competitively in Australia on automated fully computerised advanced manufacturing equipment," reports Leipnik.

"Based on preliminary meetings we have had in the renewable energy sector, we believe that there is the potential for an Australian based manufacturing enterprise producing between $90-100 million a year of solar roofing sheeting requiring between 185- 200 employees, just for the Australian market place alone.”

The Specialty Group has attracted financial support for the project from both the State and Australian Governments.