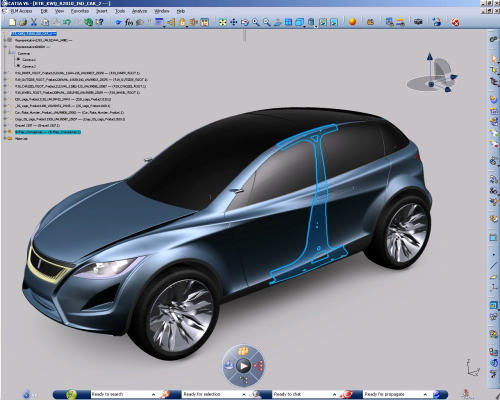

The specific composite-related features of the CATIA application allowed faster composites assemblies and components designs.

“BMW Group leveraged Dassault Systèmes’ comprehensive and integrated industry solution experiences for the design and manufacturing of composite parts and structures”, said Monica Menghini, Executive Vice President, Corporate Strategy, Industry & Marketing, Dassault Systèmes.

“Utilising composite structures gives vehicle manufacturers the innovation space they need to create new mobility experiences while meeting ever more stringent regulatory targets,” said Philippe Laufer, CEO, CATIA, Dassault Systèmes. “We are proud that our long term investment in building integrated design and manufacturing solutions for composite materials, in partnership with industry leaders, helped BMW Group revolutionise mass production of composites structures in such an impressive way. This is yet another demonstration of our commitment to bring design into the Age of Experience with our CATIA applications portfolio.”

According to Dassault Systèmes, with the CATIA Composites Design applications composites manufacturing constraints can be embedded early in the conceptual stage, enabling increased design iteration and early collaboration between design and manufacturing. Designers and producers are also able to realistically experience the manufacturing process, visualising the material fibre orientation. This helps detect any deformations that can compromise strength, quality and production due to a difference between the final product and the design intent.