KraussMaffei says that BMW will use these machines to support series production and develop turnkey process solutions.They will be used to produce and finish components made of thermoplastics and reactive resins for the interior and exterior, as well as for load-bearing structures.

Parts for the vehicle body will be produced on nine high pressure resin-transfer moulding (RTM) machines at the BMW plants in Landshut and Leipzig, Germany.

According to KraussMaffei, these machines have high filling pressures for maximum fibre wetting and self-cleaning mixing heads. They ensure a highly automated production process with great potential for shortening the cycle time. Post-mould finishing of the components is carried out based on trimming systems and the material supply system is also part of the order.

At Landshut, carbon fibre reinforced plastic (CFRP) components are being made for the BMW i3 electric vehicle scheduled for launch in 2013.

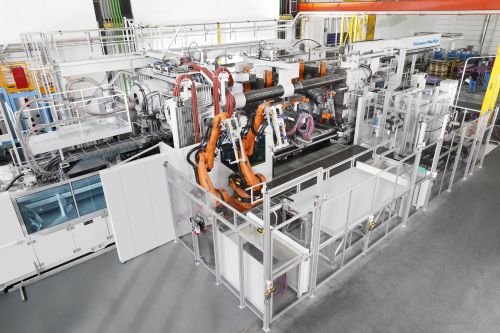

As part of the order, the BMW plant in Wackersdorf will acquire another large MX 4000-24500 injection moulding machine to produce stable mould carriers for the instrument panel in the 1 and 3 Series using the 'injection moulding structural foam' process. In this process components are produced with a compact outer skin and a foam structure inside. Two integrated industrial robots from KraussMaffei perform the necessary assembly and follow-up steps.

At the BMW plant in Leipzig two 4000 tonne MX 4000-17200/12000/750 WL double swivel-plate machines will produce components with an outer skin and a thermoplastic substructure. In this case the outer skin and substructure will each first be separately injection moulded, joined together as the two swivel plates rotate and tightly connected with a third plastic component.

The machine is fully automated with two industrial robots.