CAFE standards

64% of the nearly 900 respondents said that the US 2017-2025 CAFE (Corporate Average Fuel Economy Standards) could get more stringent as a result of the upcoming mid-term reviews.

The US Environmental Protection Agency (EPA) standards require, on an average industry fleet-wide basis, 163 g/mile of CO2 in model year 2025, which would be equivalent to 54.5 mpg (4.3 l/100 km) if this level were achieved solely through improvements in fuel efficiency.

The EPA in April released a report on vehicle greenhouse gas emissions that concluded “automakers are off to a good start,” and the US National Highway Traffic Safety Administration (NHTSA) in June published a Summary of Fuel Economy Performance report that shows auto manufacturers project fleet production is just above 34 mpg in 2014.

Lightweighting

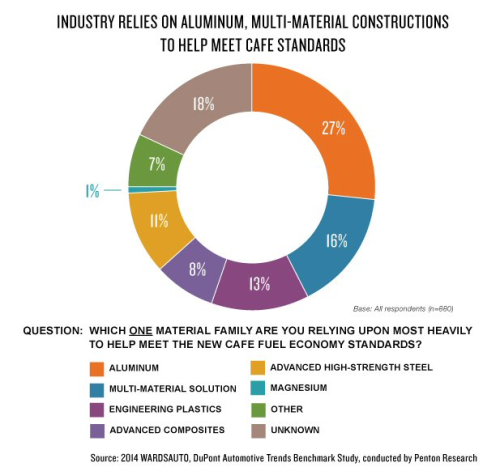

When asked which one material family they were relying on most heavily to help meet the new CAFE standards, 27% of respondents said aluminium, 16% said a multi-material (hybrid) solution, 13% said engineering plastics, 11% advanced high-strength steel, and 8% advanced composites (see chart).

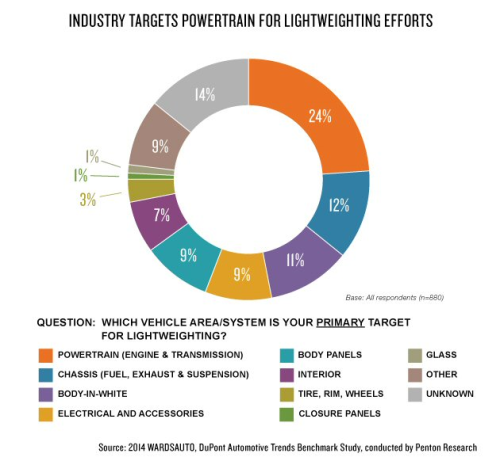

The survey found that powertrain systems (engine and transmission) are the primary target for today’s lightweighting efforts, followed by the chassis, body-in-white, body panels and electrical and accessory systems (see lower chart).

No silver bullet

When asked to rate their confidence in the ability of today’s materials portfolio to help them meet the stringent CAFE regulations, half the respondents said they were only “moderately confident.”

“That rather ‘middle of the road,’ ambivalent assessment of the material palette suggests we need to work together to continue to drive innovation,” says Jeff Sternberg, director of DuPont Automotive Technology.

“There is no silver bullet – every part and vehicle system faces a different set of requirements – but it is pretty clear that the automotive design and engineering community needs more support from advanced materials suppliers to reduce vehicle weight. The most effective approach involves value-chain collaboration to understand the needs and develop new materials, new designs, new manufacturing methods – or all three – to find solutions.

- Now in its fourth year, the DuPont-sponsored survey with WardsAuto was conducted by Penton Market Research, Overland Park, Kansas, USA. 45% of the respondents came from system, component or parts manufacturers, 25% from a car maker, and 30% from engine, engine-service, engineering/design companies or automotive-related industries. 64% of respondents work in engineering, design, research or quality roles.