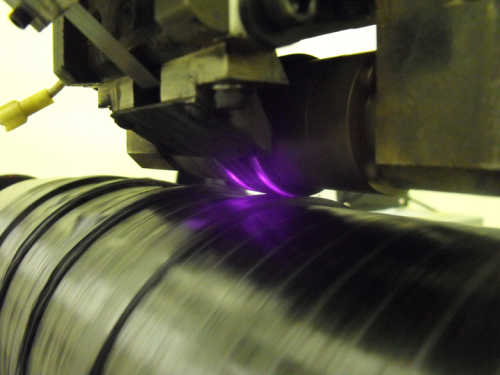

The laser-based heating method is currently being integrated into Automated Dynamics’ fibre placement equipment and will be used to replace and/or supplement hot gas for heating. "This new heating process will help us improve control over temperature in the bond zone and lead to greater efficiency," claims Robert Langone, president of Automated Dynamics, a manufacturer of composite processing equipment located in Schenectady, New York, USA.

"We look forward to using lasers for parts production in the near future and plan to make them available as an option on sales of our composite processing equipment as well. Of particular interest is the boost in processing speeds and associated gains in material throughput and consolidation quality that preliminary work with this form of energy delivery is demonstrating."

Benefits of laser use are said to include:

- improved process control;

- greater productivity;

- improved reliability; and

- high electrical efficiency.

Automated Dynamics purchased the laser from IPG Photonics in Oxford, Massachusetts. The effort is being partially funded with support from New York State Energy Research and Development Authority (NYSERDA).