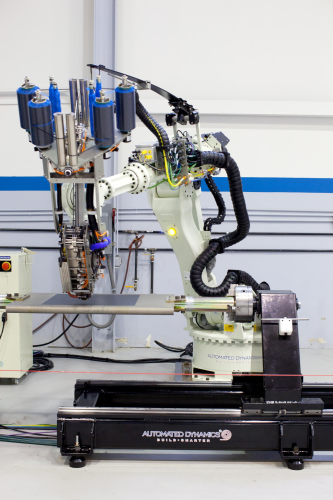

The new AFP machine, which features a four-tow Individual Tow Control (ITC) fibrr placement head, is scheduled for delivery in October 2012.

“We’re pleased to work with the Naval Air Warfare Center to manufacture a machine that will keep them at the cutting-edge of carbon fibre composite material production,” says Robert J. Langone, president, Automated Dynamics, Schenectady, New York.

“The versatility and overall efficiency of this machine’s capabilities will allow the Center to develop solutions that were previously unattainable.”

The new work cell will provide the Naval Air Warfare Center with the ability to produce an array of complex structures and geometries. It will be installed in the composites lab on the China Lake Naval Base in California.

Benefits of the machine include:

- increased production versatility, allowing for greater control in the placement of composite tapes;

- improved throughput;

- reduction in scrap; and

- expanded capabilities across various applications with a variety of material systems.

Automated Dynamics has also been contracted to provide the Naval Air Warfare Center with training on the use of the machine, how to maximise the benefits of the ITC fibre placement head and fibre placement production.