The Composite Crew Module (CCM), a first for NASA, is a space capsule design that has the potential to reduce the overall weight of future manned launch vehicles.

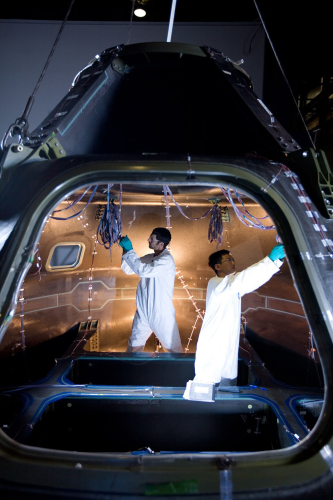

Composite structures reduce launch costs through weight savings and are presently used on a variety of space launch vehicles and aerospace structures. The CCM is unique in that it was specifically designed and built to resemble a space capsule.

Full-scale structural testing will be performed at NASA's Langley Research Center to determine the strength and viability of the composite structure. During the destructive testing, the CCM will be placed under load conditions similar to those observed during launch, on-orbit, landing, and abort scenarios.

Led by the NASA Engineering and Safety Center (NESC), ATK was part of a team of NASA and industry experts which designed and fabricated the CCM to demonstrate how composite materials could be used to develop a pressurised space capsule. ATK provided composites design, analysis, manufacturing and assembly expertise for the Composite Crew Module programme.

The CCM was fabricated and assembled at ATK's Iuka, Mississippi, USA, facility. It consists of two primary sections. The upper and lower shells are joined together with a splice joint and cured using out-of-autoclave technology.

"ATK has decades of experience in building composite structures for launch vehicles, military aircraft, and most recently commercial aircraft such as the Airbus A350," says Jack Cronin, President, ATK Mission Systems. "We have applied our innovative engineering and manufacturing capabilities to help the CCM team build a cutting-edge, composite space structure. We demonstrated our ability to perform, partner and deliver an advanced composite structure that's never been built for NASA."

ATK (NYSE: ATK) is a composite manufacturer and supplier for modern military and commercial aircraft, and space launch vehicles.