The new tooling systems are designed to work with Amber’s growing range of component prepregs.

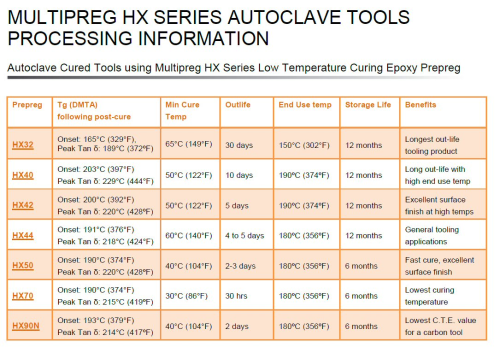

HX series tooling has been in use worldwide for nearly 25 years and is known for excellent performance and ease of use. New additions to the line include HX32 and HX40, which enable larger tools with extended out-life, and HX44 with similar properties but specially formulated for glass tooling.

The HX32 product has been successfully trialled by Multiplast.

“After successfully using Amber’s HX42 tooling system, we tested their new HX32 tooling prepreg, in both 200 g/m2 and 650 g/m2," reports Jean-Baptiste Mouton, Composites Engineer at Multiplast.

"The handling of the material has been easy, with good tack and drapability. Curing at 70°C for 12 hours was convenient and yielded a good surface finish and tool quality. For tools made to mould 120°C parts, we will now be using this material in production.”

According to Jonathan McQueen, Managing Director at Amber Composites based in Langley Mill, Nottingham, UK, the company is developing new component prepreg, including fire retardant systems, toughened systems, and out-of-autoclave systems, while extending its tooling range.

“The second half of 2012 will see quite a few new component and tooling prepregs coming to market,” he says.

Amber Composites won recognition from the British government recently when it chose Amber as one of the stars of British manufacturing. UK Trade & Investment (UKTI) also recently acknowledged Amber for its strong export business.