The ACG GRAFOAM FPA-20 Carbon Foam Tooling System has a coefficient of thermal expansion (CTE) of 2.3 x 10-6/°C and is said to have a thermal resistance that “exceeds composite processing requirements.”

It can be machined to near-finished size and can be fully encapsulated in ACG’s compliant interface technology and a tooling laminate skin such as ACG’s low temperature moulding (LTM®). It also allows for higher temperature resin systems from ACG’s medium (MTM®) and high (HTM®) temperature tooling laminate ranges.

Once cured, the final tool profile is created with a second machining operation minimising shrinkage, spring-in/spring-out, and pattern/laminate CTE mismatch.

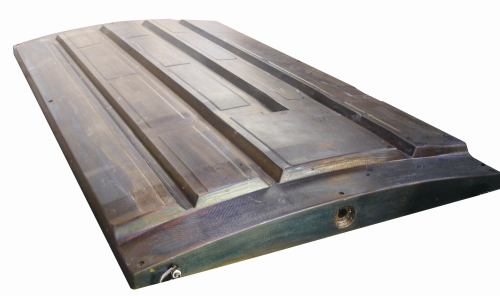

Tools manufactured from the ACG GRAFOAM FPA-20 Carbon Foam Tooling System are said to be fully self-supporting, and are suitable for traditional and emerging composite process methods, particularly tape placement and filament winding.

Large development tools manufactured at ACG’s facilities for an undisclosed “major aircraft manufacturer in North America,” have achieved dimensional accuracy of 0.2 mm on complex surface profiles, but with the vast majority falling within ± 0.1 mm.

According to ACG, the high thermal resistance of the carbon foam tooling system offers advantage and cost savings when manufacturing high temperature (BMI) tooling. ACG BMI prepreg, for example, can be cured directly onto the foam core in a single operation without the need for a heat-resistant intermediate splash tool, and then machined to the requisite final profile.

ACG of Heanor, UK, is a member of the Composites Division of Umeco Plc. GRAFOAM is a registered trademark of GrafTech.