ACG andJD Lincoln manufacture epoxy, cyanate ester, bismaleimide and phenolic prepregs for use in a wide range of industries.

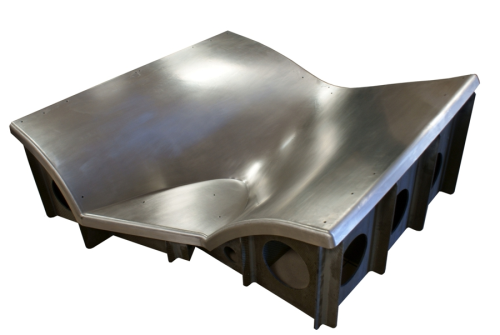

At SAMPE Tech the companies will showcase an award winning tooling solution jointly developed by ACG and Integran Technologies Inc: Carbovar - Nanovate - NV surface composite tooling. This combines the hardness, durability and damage tolerance of a nanometal coating with the lightweight, low thermal mass of a carbon fibre composite mould tool.

The Nanovate surface is an ultra-hard, nanocrystalline nickel/iron alloy coating that has a low coefficient of thermal expansion (CTE) matching the CTE of the composite mould tool. The ultra-hard surface increases the longevity of the mould, becoming comparable to that of a conventional metallic mould tool.

Composite tooling saves the energy required for the heat-up and cool-down phases, and the energy required to lift, rotate and manoeuvre the tooling within the working environment, and during the lay-up process (faster material deposition rates).

The SAMPE Tech 2011 conference and exhibition takes place in Fort Worth, Texas, USA, on 18-20 October.