3M Matrix Resin is designed for carbon fibre prepreg applications. The resin has been optimised to increase modulus and toughness without compromising key properties. 3M claims the resin is ideal for sporting goods and other high performance carbon composite structures that require improved compression strength and reduced crack propagation. 3M has conducted extensive testing of its new resin compared to standard epoxy resin technology. The tests showed the following results:

- 76% improvement in shear modulus;

- 73% improvement in toughness; and

- 68% improvement in Barcol hardness.

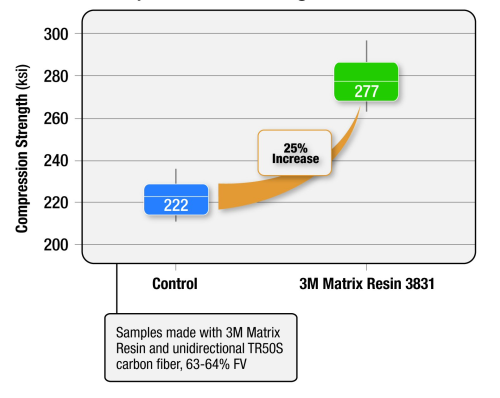

In composite structures, 3M Matrix Resin 3831 shows the following results:

- 25% improvement in compression strength: compression strength = 277 ksi; and

- 49% improvement in in-plane shear stiffness: G12 = 5.7 GPa.

“The fundamental weakness of carbon fibre is a limitation in compression strength,” says John Horn, Vice President of Research & Development for 3M Industrial & Transportation Business. “Because our new product is a higher modulus resin, it supports the fibre to reduce or delay micro-buckling, resulting in a stronger, longer lasting product."

"By creating products that are more durable and lighter weight, you are increasing product performance while decreasing the chance for material failures," he continues. "This means fewer returns and warranty claims, and more satisfied customers.” According to Horn, carbon fibre prepreg tapes manufactured using 3M’s Matrix Resin have the same processing characteristics as standard prepregs and can be used in a manufacturer’s prepreg lay-up process without modifications. Cure is initiated at the same temperature and the resin has similar flow properties to typical 250°F cure prepreg resins. The new resin is offered by 3M Industrial Adhesives & Tapes Division, based in St. Paul, Minnesota, USA.