The FlexiCut finishing option consists of an intelligently arranged grooving pattern which doesn’t require any scrim material or specially drilled holes. It is very cost efficient, reports 3A Composites Core Materials.

FlexiCut core materials are suitable for use in hand lay-up, resin infusion and prepregs processes.

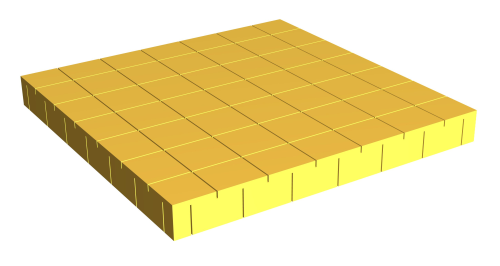

FlexiCut offers:

- very thin grooves of 0.7 mm width, which reduce resin consumption compared to conventional sawed ContourKore or Double Cut configurations;

- asymmetric cut depth configuration (85% and 20% respectively of the sheet’s thickness) offering very good sheet contourability both in positive and negative directions;

- grooves on both sides and clearly defined holes in the groove intersections guarantee a good resin flow and distribution.

3A Composites Core Materials produces two product families: AIREX® polymer foam core materials; and BALTEK® balsa wood.