This article excerpt is taken from the September/October issue of Renewable Energy Focus magazine. To register to receive a digital copy click here.

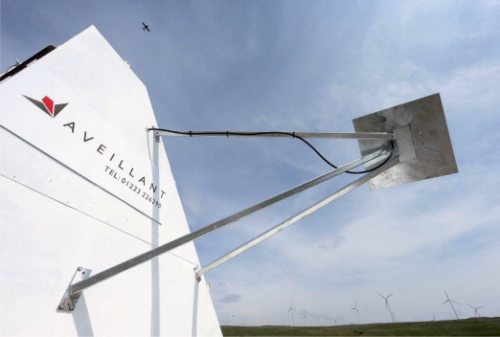

According to David Crisp, CEO of wind turbine mitigation technology company Aveillant, wind turbine developers need worry about radar no more.

The company has just finished a round of testing on its Holographic 3D wind turbine mitigation system on radars at Prestwick Airport, Glasgow, UK – and Crisp is so pleased with the results that he is prepared to say that the radar thorn in the wind developer's side is soon to be banished.

“As soon as we've got this commercial next year, it's done,” he tells Renewable Energy Focus. “Holographic radar, because it is so good, and integrates so seamlessly, we have literally put the airport radars back to how they were before wind turbines were built. So when we start shipping next year, we would like to be able to say the problem's gone.”

Most wind developers will take this statement with a dose of cynicism – every technology on the market has some claim to be the breakthrough solution – but the truth is that experts within the wind sector and the aviation sector alike are starting to recognise that real progress is being made towards solving this problem.

“Radar interference has presented an issue for wind farm development for over 11 years,” says Nicola Vaughan, director of wind energy at Osprey Consulting, which has consulted on aviation issues for a number of big UK wind projects. “Now, at long last we are witnessing some truly innovative mitigation solutions reaching maturity, and being installed for the first time.”

True, some technological silver bullets have fallen at the first hurdle: Vestas, which was developing the much-vaunted “stealth blade” designed to be invisible to radar, ceased its work on the project in 2012, citing a lack of market opportunities, most likely linked to cost of deployment.

But New York-based C Speed, which, like Aveillant, offers a retrofit “infill” solution, has recently signed a deal to install its Lightwave wind turbine mitigation system at the 17-turbine extension of Vattenfall's Kentish Flats offshore wind farm off the coast of the UK – believed to be the world's first commercial installation of such a system, as well as the first to go through the stringent regulatory process required by the global aviation industry.

Meanwhile, a host of other retrofit solutions purporting to solve the issue by digital display manipulation, radar overlap or processor upgrades are waiting in the wings pending testing, regulatory approval and commercial launch.

Wind turbine “clutter”

In layman's terms, while most primary surveillance radar (PSR) systems are able to distinguish between aircraft and stationary objects like the turbine towers, rotating wind turbine blades mimic the movement of passing aircraft and often get picked up by radars used by military and civilian air traffic control and military air defence systems. This causes clutter on the radar operator's digital display, creating false readings or screening real aircraft from view.

For the aviation sector – both civilian and military – this inability to accurately identify aircraft flying over wind farms presents a serious safety problem. Air traffic controllers have often resorted to diverting aircraft around wind farms to circumvent the problem, usually at a distance of 5 nautical miles.

However, this comes with a cost, of both fuel and carbon, and as wind farms have proliferated, this option has become increasingly restricted. As a result, wind developers have often found their efforts to progress their projects frustrated by safety and operational objections from the aviation authorities.

There is very little data available to show exactly how many GW of capacity is blocked globally by aviation objections, but there are some clear hotspots. The most recent data from Europe was collated in 2011, suggesting that up to 19GW of wind capacity could be delayed or blocked as a result of aviation concerns – with the UK, Finland, Sweden, Germany, the Czech Republic, Greece, Ireland, France and Spain all identified as problem areas.

The UK constituted around 63% of this, reflecting both the size of the UK's wind market and the high concentration of radar: including over 60 military and civilian radars.

Solutions on the way?

So far, the solution favoured by most wind developers, and indeed radar operators, has been to approach each objection on a case-by-case basis and make adjustments to the project – for example reducing the number of turbines – or operational adjustments to the radars themselves, altering the algorithms or reducing the range.

“In a lot of situations, the problem is surmountable,” says Jacopo Moccia, head of the European Wind Energy Association (EWEA)'s policy analysis unit. “There will be places where you can't put the turbines. It is a question of goodwill on both sides: from the developer's side and from the radar operator's side.”

This approach has worked on a number of cases in the US, where the Federal Aviation Authority (FAA) holds legal jurisdiction over all structures over 200 feet in height, and where the Department of Defense reserves the right to block all projects it sees as a threat to its military systems.

“If potential objections are identified early enough, then concerns can often be worked through and resolved,” says Tom Vison, senior director of federal and regulatory affairs at the American Wind Energy Association (AWEA): “When concerns only become apparent late in the process, it is more problematic. The wind energy industry and the relevant Federal agencies have been improving communication and finding ways to engage earlier in the development process, which has been helpful.”

But what about when this approach fails?

Certainly, the fact that many of the PSR radar systems in use around the world date back to the Cold War era presents a problem, and limits the possible adjustments that can be made. And at this point a more complex technological solution is sought.

One answer is to install upgrades to the existing system, something that has only been made possible in recent years by technological advances in processor components. BAE is working on a wind farm mitigation upgrade to its Watchman radar system, currently in use at a number of Royal Air Force (RAF) bases in the UK, while US Government tests on a processor upgrade to Raytheon's air surveillance radar in Tyler, Minnesota last year found that it improved the system's ability to detect real targets.

Another option is to combine the existing primary surveillance radar with secondary surveillance radar (SSR). While PSR sends out a pulse to detect the movement of an object, it cannot detect its altitude, which is why it is easily confused by wind turbine blades. SSR communicates with a transponder inside an aircraft which communicates its exact location as well as its altitude. By patching the two signals together, radar operators can more accurately distinguish between the two.

However, this is not a failsafe solution for all markets. In the UK, for example, there is a large community of “general aviation” craft; such small aircraft, micro-lights and gliders do not have a transponder fitted.

Nevertheless, solutions which involve patching together different signals appear to be the most promising. In the UK, air traffic control service (NATS) uses its myriad of radars to offer its own wind farm mitigation service. Otherwise known as “blanking and infill”, NATS blanks some radars affected by wind turbines and patches in signals from others which are not to “infill” the gaps to create a more accurate radar picture.

However, while this solution is available immediately, there are limitations, not least that the integration of the data is not seamless, potentially leaving gaps. Moreover, it is only possible in countries where there is significant overlap of radars managed by the same system, such as in the UK, and is less likely to be successful in larger areas such as the US.

Other infill solutions put forward by companies such as Aveillant and C Speed, seek to resolve this issue. New, smaller radar systems are installed, either inside the wind project itself or nearby, which then integrate with air traffic control systems to distinguish between aircraft and turbine blades.

In Aveillant's case, the radar “looks” directly upwards at the sky, and once integrated with the PSR system, gives a “3D” radar reading in real time, Crisp claims.

US tests of C Speed's Lightwave in Minnesota, meanwhile, found that the technology was very successful at detecting aircraft around wind farms, albeit with a higher false alarm rate.

However, there are drawbacks. Resolution infill can be a high-cost solution, requiring expensive infrastructure additions that take up precious space on the S-band radio spectrum – although Aveillant says that the spectrum issue does not affect its system – set to be crowded out by Ofcom's recent sale of 4G bandwidths.

No panacea

The question of which solution is most effective is yet to be answered. “There is not a single solution that will work everywhere because the potential impact, radar type and location, topography and so on will vary,” says the AWEA's Vison. “What we need is a variety of solutions at a variety of price points so industry and the Government can best match an affordable solution in a given situation.”

Osprey's Vaughan agrees. “It depends,” she says, when Renewable Energy Focus asked which solution was most promising:

“Different solutions have their own merits, and therefore applicability to varying degrees of complexity of airspace. If the airspace is critical, for example on the centre line of a runway used for radar approaches, the mitigation will have to be very robust, with little or no degradation to the overall performance of the radar in that area. This presents a different requirement to if the wind farm was in a non-critical piece of airspace, and the issue was that the clutter presented an unmanageable distraction to controllers.”

One solution, of course, is to replace the old radar systems with new, wind-resilient radars. The UK's MoD has brought forward the replacement of three of its seven air defence radars, which had been threatened by some of the UK's east coast offshore wind projects. As a result, the projects have now been given the go-ahead. However, this is an extremely costly solution, and in this case the upgrades were financed by the wind developers themselves, something which many in the wind industry consider unsustainable.

“I don't think we can say that wherever it is a problem wind power developers will just buy a new radar,” says Jacopo Moccia, head of EWEA's policy analysis unit. “It's not fair for a start and it's not going to work everywhere anyway.”

Aveillant is hoping to circumvent this problem by offering a mitigation service, as opposed to a buy-own-operate model. “The problem with [collaborative funding] is that wind farm development is extremely difficult to predict: knowing when you'll get a project approved and consented is very difficult. So, getting wind farm developers to collaborate to make a fund is very difficult.

“We decided that the best thing we could do is supply the technology, but also if we finance deployment of our own radar stations, then it will help unlock that logjam that we see.”

Vaughan believes that the key to solving the problem once and for all lies within the aviation sector, and its ability – or otherwise – to think strategically about wind turbine mitigation. Osprey is currently assisting a handful of independent airports to take a strategic view of mitigation, identifying what solutions are available to implement in the short and long term, which she says will accelerate progress towards a truly global solution.

Ultimately, however, the radar issue could form part of a wider political objection that will require more than technology to solve.

“This problem has come up most often in countries where there was a generalised political resistance to wind farms anyway,” says the EWEA's Moccia. “Once you've brought down the political resistance, all the other planning restrictions, whether they are birds, radar, bats, aesthetic impact and so on you can work around – because there are ways of doing that. If the stance is: no wind energy, then [opponents] just throw everything they have at the industry, including the radar issue.”

Further reading

- Progress made on wind farm friendly radar

- Scotland to press on with wind plan despite Trump objection

- A higher height data wakeup call

- Community, crowd and conversion

About: Rachel Parkes is a freelance journalist based in the UK covering energy issues.