Materials from renewable resources – also called biomaterials or 'green' materials – are presently gaining in importance worldwide. In these times of continuous increases in the price of crude oil and discussion of carbon dioxide (CO2) emissions, conventional plastics have reached a price level and a questionable image which promotes the search of alternatives.

Two of these alternatives are natural fibre-reinforced plastics (NFRP) and wood plastic composites (WPC). These are composites that are typically filled or reinforced with plant fibres and wood flour respectively, as well as plastics such as polypropylene (PP), polyethylene (PE) or recently, even bioplastics. Therefore a large variety of products is possible with the injection moulding technology.

High market growth

In the past years, the nova-Institut in Hürth, Germany, has conducted numerous studies in the field of biomaterials in general on behalf of private or public clients, producing a unique set of data. The most important, often never before publicly presented, data and trends for the German and European market are listed for different industries (construction, furniture, vehicle construction, consumer goods etc.) for the material groups of NFRP, WPC and 'bioplastics.' Summarising the results, one arrives at the impressive figure of about 350 000 tonnes of biomaterials used in Europe. This amount is comprised of almost equal shares of the three material groups.

In terms of industries, the automotive industry (mainly compression moulding with natural fibre-reinforced thermosets), packaging (biodegradable packagings) and the construction industry (extruded WPC products) are dominating. As for production methods, injection moulding is continuing to gain in importance and is making it possible to penetrate new markets, mainly in the furniture, consumer goods and electrical industries. In the future, a further fusion of the material groups, for example, into natural fibre-reinforced bioplastics, is expected.

During the last two years in particular, a couple of positive trends have became evident. For example, German WPC production volume has risen from 5000 tonnes in 2005 to about 20 000 tonnes in 2007. nova-Institut estimates that the present production volume in Europe is about 100 000 tonnes. Germany/Austria, Benelux and Scandinavia are the leading regions. These figures refer to the building, construction and furniture industries. In the European automotive industry, another 50 000 tonnes of WPC are used per annum.

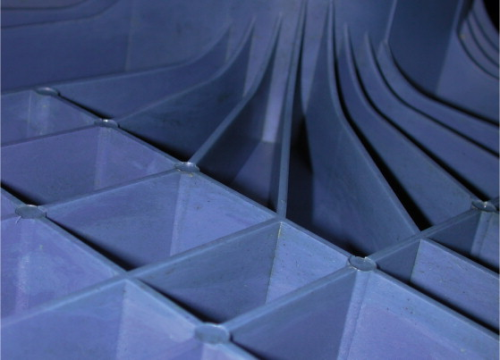

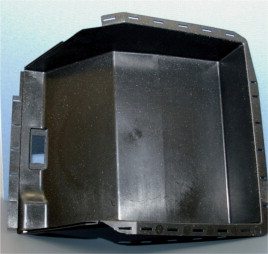

Terrace flooring is the most important sales market for WPC, which has a market share of about 6% in this sector. A rise to 20% is considered possible during the next years, mainly as the material becomes a substitute for tropical hardwoods. WPC is also experiencing significant increases in application in the furniture industry, where well-known suppliers now have a number of chairs and shelving systems made from WPC in their product ranges. Important selling points are using the conventional plastic injection moulding process – but now with a wood material! – and the attractive finishes which can be achieved. Depending on the formulation used, wood fibre is easily identifiable and can also be dyed, and its texture also bears greater similarity to a wood material in terms of warmth and grip than plastic. In addition, panel materials made from WPC have been a firm fixture in automobiles for many years as rear parcel shelves and interior door linings. These are laminated with standard types of textiles and simulated leather materials.

Natural fibre reinforced plastics are employed mainly for their good technical properties; these can be applicable even in the field of glass fibres. Therefore they are regarded as a real enhancement. An outstanding example of this is the carrier for a grinding wheel of which millions of units have been sold worldwide. This does not only meet the mechanical requirements, but it is also advantageous in the areas of occupational health and safety.

|

PA 66: Polyamide 66 PA 66-GF: Polyamide 66/glass fibre reinforced PC/ABS: Polycarbonate/acrylonitrile butadiene styrene POM: Polyoxymethylene PP: Polypropylene PP-GF: Polypropylene/glass fibre reinforced PP-NF: Polypropylene/natural fibre reinforced PP-T: Polypropylene/filled with talcum |

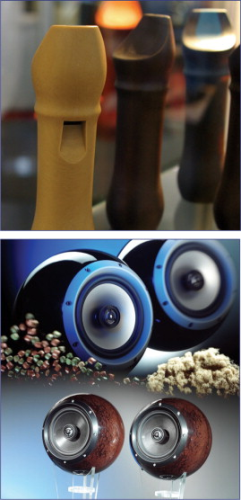

Other successful products include, for example, loudspeaker enclosures that are installed both beneath the surface in the automotive interior, and traded as design objects in the high-end sector. There is a general trend towards systematically integrating the natural fibre look into an ecologically-oriented marketing concept. While years ago, the first product developments failed partly just because of their appearance, this 'mottling' is today an identifying feature. For example, there are toys, cosmetic packagings and household appliances in which natural fibre reinforced plastics are intentionally present in the field of vision.

A pleasant and at the same time slip-proof and cushioning texture is the most remarkable feature of applications containing cork; in particular the grips of sports goods and tools have to be mentioned here. Other developments presently on the engineers’ desks are expected to become further essential product innovations in the future.

Market drivers

| New biomaterials - processes & applications | Quantities (regions) |

| Biodegradable bioplastics (packaging, catering) | 60 000-70 000 tonnes (W. Europe 2007) |

| Bioplastics (durable applications) | 30 000-40 000 tonnes (Germany 2007) |

| Compression moulding with natural fibres (automotive industry) | 29 000 tonnes (Germany 2005) |

| Compression moulding with wood fibres (automotive industry) | 40 000 tonnes (Germany 2005) |

| Compression moulding (trucks) | 79 000 tonnes (Germany 2003) |

| Injection moulding & extrusion with wood plastic composites | 80 000-105 000 tonnes (EU 2006) |

| Injection moulding & extrusion with natural fibre reinforced plastics (consumer durables etc) | 3000-4000 tonnes (EU 2006) |

| Total | at least 350 000 tonnes in the EU |

Discussions about CO2 reduction, climate protection and sustainability have shaped reporting in the media for some considerable time now and this has had a knock-on effect on people's purchasing behaviour. As a result, many companies in the plastics processing industry are already looking intensely at new, non-oil related materials. Natural fibre reinforced plastics (NFRP) are often an economically viable alternative, and what's more, when compared to non-reinforced plastics, they also deliver technical and environmental added value.

For example, the cumulated energy demand (CED) in the production of hemp fibres amounts to only 10% of the energy demand in glass fibre production.

Technological development of these materials is more advanced than ever before and the production costs are now thoroughly competitive. Polypropylene natural fibre injection moulding compounds (PP-NF) and WPC in particular represent attractive alternatives to the hitherto mass-produced plastics. Accordingly, the industry has expressed great interest in these 'eco-friendly materials.'

A multitude of bio-materials

The range of natural fibre-reinforced products already available today represents a cross-section of all materials: from mundane grass, to traditional flax and hemp fibres, elastic cork and (currently all the rage) wood fibre to exotic bamboo. It's been a long time since the binding matrix had to be a petrochemical polypropylene or polyethylene: many producers already have recipes based on eco-friendly polylactic acid (PLA) in their product range.

As well as developments in terms of quantity, there have also been important advances in quality, with current products able to fulfil customer expectations in the important areas of mechanical stability, durability and colour fastness.

The first European quality mark, which was launched in December 2007 at the Second WPC Congress in Cologne by the Verband der Deutschen Holzwerkstoffindustrie (VHI or Association of German Wood-Based Panel Industries), attests to a new assertiveness in the industry.

An award for innovation in WPC was also presented at the Second WPC Congress in Cologne. The patrons were the nova Institute and Reifenhäuser Grou. Declared a clear winner in the Product category was the Extrusoregal shelving system made of extruded WPC hollow chamber profiles with patented injection moulded clamp joints. This enables the remarkably lightweight shelving to be packaged and dispatched in the required lengths and then individually assembled by the customer. (More details about this product are available on the website www.mehrwerkdesignlabor.de).

| Fibre plants | Area under cultivation (ha) | Production (tonnes) | Main cropping areas |

| Jute* | 1 343 620 | 2 859 105 | India, Bangladesh |

| Flax* | 504 995 | 770 467 | Europe, China |

| Sisal** | 375 687 | 315 573 | Brazil, Tanzania, Kenya |

| Jute-like* (kenaf etc) | 296 241 | 382 581 | India, Bangladesh |

| Abaca** | 146 63 | 100 457 | Philippines, Ecuador |

| Hemp* | 52 307 | 67 818 | China, Europe |

| Coir*** | only by-product | 398 600 | India, Sri Lanka |

It was a somewhat closer decision in the Process category, where the linear vibration welding process for the production of Fibrex™ joints in window construction by Swiss company Fentech AG won first prize, just ahead of the recipe and process development for the manufacture of WPCs from MDF dust generated in the production of furniture by Zeulenroda-based Reinü-Fefa Produktions GmbH.

Disillusioning reality

Despite the high quality of the materials, the long years of experience and a positive marketing message, up to now there has been a relatively low market penetration in the EU: a maximum of 20 000 tonnes in 2006 for NFRP and WPC injection moulding in consumer goods, special applications as well as the automotive, building and furniture industries. The reasons are manifold and also very individual: it is still a young material group that up to now has been perceived as a speciality material rather than a mass-produced material, and it is available in relatively small amounts. For the most part, small- and medium-sized businesses are involved in this industry. They can offer only limited support and service, and guarantee security of supply only to a limited degree, and they do not have comparable competitors which could step into the breach in extreme situations. That's why single suppliers are not accepted by most (major) customers as sub-contractors.

|

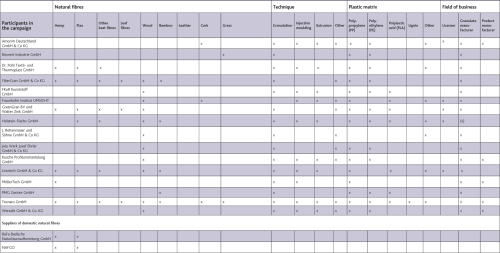

The nova-Institut is running the Campaign for the Industrial Implementation of Polypropylene Natural Fibre Injection Moulding (PP-NF) and Wood Plastic Composites (WPC) – Part II, project number 22018706. Its goal is to establish an industrial market for PP-NF and WPC granulates on a long-term basis. By means of targeted marketing, it is planned to increase the level of awareness of industrial decision makers towards these new materials and their manufacturers. Furthermore designers and engineers will receive qualified data and technical information for their future product developments. For the realisation of these goals, an interdisciplinary group of scientists, engineers and marketing experts has teamed up. One element of the campaign is a product catalogue: in this 16 leading manufacturers and developers (see Table 2) as well as the four project partners introduce themselves and their products and services. The variety of manufacturers ranges from innovative one-man companies to global players, but they all have one thing in common. They offer products for the industrial market, whether granulates for injection moulding and extrusion, NFRP parts, or production licenses. The catalogue is available as a PDF file free of charge or as a hard copy. The project is funded by the FNR (Agency for Renewable Resources) in Gülzow which is part of the Federal Ministry of Food, Agriculture and Consumer Protection. The project was started in March 2007 and will run until December 2008. For further information take a look at www.n-fibrebase.net; there you can also order the 84-page product catalogue (available in German only). Note: In the framework of the campaign the nova-Institut has tried to identify all the actors in the field of natural fibre injection moulding in Germany and Europe, also trying to get them enthusiastic about the project. Here injection moulding and extrusion were ithe focus of attention. In the future, a new edition of the product catalogue, as well as an extension towards further techniques, is planned. Interested companies can contact nova-Institut. |

In general the materials and their potential still are little known amongst designers and decision makers. Also the technical know-how about specific construction and processing of the material is not well-known enough amongst a majority of designers and engineers. As a result, there is a lot of scepticism and a lack of willingness to make use of this material group.

But despite these drawbacks, it is to be expected that the positive trend with two-digit growth rates will continue in the next years. With the entry of big, globally active and well-known actors such as IKEA, UPM Kymmene, Wacker Polymers or REHAU – just to mention a few – the gateway towards a high-quality mass-produced material is wide open, especially for WPC.