The Airbus report identifies a need for a total of some 28,200 passenger and freighter aircraft (of 100 seats or more) between 2012 and 2031, worth nearly US$4 trillion.

Of these, over 27,350 will be passenger aircraft, valued at $3.7 trillion.

Growth in passenger traffic

- Passenger traffic will grow at an average annual rate of 4.7% in the next 20 years, during which some 10,350 aircraft will be replaced by new efficient models, Airbus predicts.

- By 2031 the world’s passenger fleet will have expanded by 110% from slightly over 15,550 today to over 32,550.

- In the same period, the world’s freighter fleet will almost double from 1,600 to 3,000 aircraft.

- There is growing demand for eco-efficient aircraft – two thirds of the existing fleet will be replaced.

Growth in emerging regions

Emerging economic regions will represent more than 50% of all traffic growth in the next 20 years.

|

Boeing's latest figures (Current Market Outlook 2012-2031) offer a slightly higher forecast than Airbus, with passenger traffic growing at a rate of approximately 5% per year. Boeing predicts demand for 34,000 new aircraft, valued at $4.5 trillion, with some 13,940 aircraft being replaced by new, more efficient models. Boeing flagship model, the 787 Dreamliner, can carry 210-290 passengers in two variants. Delivered to its first customer in 2011, Boeing says the Dreamliner uses 20% less fuel than current aircraft of a similar size. Composite materials make up 50% of the primary structure of the 787 including the fuselage and wing. The carbon fibre composite fuselage is produced as several barrel sections that are subsequently joined together. In September, Boeing and American Airlines showcased a Next-Generation 737-800 aircraft known as ecoDemonstrator in Washington, D.C., to highlight testing of technologies and advanced materials that make aircraft operate more efficiently and produce fewer emissions and less noise. The FAA program known as CLEEN (Continuous Lower Energy, Emissions, and Noise) provided funding for the adaptive trailing edge on the airplane as well as some flight test costs. Other technologies on the 2012 ecoDemonstrator include variable area fan nozzles, active engine vibration reduction, a regenerative fuel cell, and testing of flight trajectory optimization to enable more efficient routing for fuel savings. |

Increasing urbanisation and the doubling of the world’s middle classes to 5 billion people is also driving growth.

By 2031 the number of 'aviation mega cities' will more than double to 92 and over 90% of the world’s traffic will be between or through these points. Airbus's flagship model, the A380, the world's largest commercial aircraft, links these cities. According to Airbus, an A380 takes off or lands every 7 minutes. The A380's structure is 25% composite, leading to reduced weight and improved fuel efficiency (see box below).

“Aside from growth in international traffic, by 2031 four of the world’s biggest traffic flows will all be domestic – US, China, Intra Western Europe and India – and these account for a third of world traffic,” says John Leahy, Airbus Chief Operating Officer Customers.

“In 20 years from now, China’s domestic passenger traffic will overtake the US domestic traffic to become the number one traffic flow in our forecast. Aviation is not just essential for international commerce, but also for domestic economies too.”

Asia Pacific will account for 35% of all new aircraft deliveries, followed by Europe and North America with 21% each. In value terms, the single biggest market is China followed by the US, UAE and India.

Aircraft type

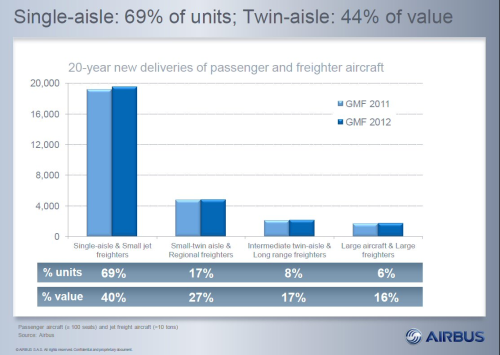

Over 1,700 Very Large Aircraft (VLA - 400 seats and above) like the A380 will have been delivered by 2031, valued at $600 billion. Of these over 1,330 are passenger aircraft valued at some US$500 billion (13% by value of passenger deliveries, 5% of units).

Asia Pacific leads demand (46%) for these high capacity aircraft, followed by the Middle East (23%) and Europe (19%).

Demand for twin-aisle aircraft (250-400 seats), like the A330 and the A350 XWB, some 6,970 new passenger and freighter aircraft will be delivered valued at some US$1.7 trillion. Of these, 6,500 are passenger aircraft valued at US$1.6 trillion (44% by value of passenger deliveries, 24% of units).

Leading demand is Asia Pacific (46%), Europe (17%) and the North America (13%).

In the next 20 years, over 19,500 single-aisle aircraft worth over $1,6 trillion will be delivered (43% of passenger deliveries by value, 71% by units). A third of deliveries will be in Asia Pacific followed by North America (25%) and Europe (22%).

Some 30% of all deliveries in this category will be for Low Cost Carriers.

Sustainable growth

The aviation industry is under pressure to become more environmentally sustainable. This includes the reduction of fuel useage and emissions and the industry itself has set an aggressive target to reduce aviation emissions by at least 50% by 2050.

Today, Airbus spends more than 90% of its €2 billion annual R&D budget on technologies that have environmental benefits for current and future aircraft. Part of this investment is used to develop new aircraft that generate fewer emissions and less noise, while carrying a larger payload over longer ranges. ♦

|

Airbus’ 21st century flagship – the A380 – entered service in 2007. The double-deck A380 is the largest commercial aircraft flying today, with capacity to carry 525 passengers in a three-class configuration, and it has set a new benchmark for fuel efficiency and low noise levels. The A380 was also the first commercial aircraft to incorporate as much as 25% composites, with its lightweight carbon fibre reinforced plastic (CFRP) centre wing box saving up to 1.5 tonnes of weight. (According to Airbus, the A380 is 15 tonnes lighter than it would be if made entirely of metal.) As a result, the aircraft has a very low fuel burn of less than 3 litres per passenger per 100 km. Airbus says in-service experience has shown a fuel consumption of 20% less than its nearest competitor. The Airbus A350 XWB, scheduled to enter service in the second half of 2014, will push this envelope even further. With three versions, accommodating 270-350 passengers, this twin aisle aircraft brings together the latest in aerodynamics, design and advanced technologies to offer 25% less fuel consumption than current-generation aircraft. Over 70% of A350 XWB’s airframe is made from advanced materials, combining 53% of composite structures with titanium and advanced aluminium alloys. The use of these materials reduce the new aircraft’s overall fatigue and corrosion maintenance tasks by 60% per cent. The aircraft features a carbon fibre reinforced plastic (CFRP) fuselage and wings. The fuselage is made by assembling four-skin panel sections – two lateral side panels, one at the crown, and another for the belly – onto carbon fibre frames. In contrast to other composite aircraft, this construction technique allows for a tailoring of composite layup thickness to each panel, based on calculations of local fuselage stresses and loads. Composites also play a big part in the Airbus Concept Plane. This illustrates what air transport could look like in 2050 and is a representation of the main technologies that are being explored to meet future needs: a significant cut in fuel burn and emissions, less noise and greater comfort. The fuselage is no longer a simple tube but is curved and shaped to provide more internal space for various cabin configurations, with better aerodynamics outside to improve flight. The fuselage and entire aircraft structure is manufactured entirely from composite which can be shaped into the required design. |

Further information

- Airbus takes on Boeing with composite A350 XWB This feature compares the construction of Airbus' A350 XWB (extra widebody) with competitor Boeing's B787 Dreamliner. Both have an airframe of over 50% composites.

- Airbus A350 XWB update Here we review the progress of the A350 XWB development programme, with a focus on the composite components.

- First A350 XWB wing arrives in Toulouse for ground tests – pictures Pictures of the first wing for the A350 XWB at Airbus’ final assembly line in Toulouse, France. The A350 XWB wing covers are 32 m long by 6 m wide, which Airbus claims makes them the biggest single civil aviation parts made from carbon fibre composite material.

- Boeing's 787: trials, tribulations, and restoring the dream. A review of this high-profile composites project.