Carbonia Composites AB acts as a development partner and supplier of components for a new class of ground-breaking, ultra compact satellite transmission systems totally dependent on carbon fibre resin transfer moulding (RTM) technology. They are used by leading broadcasters around the world as well as several defence organisations including the US Special Operations Command.

The transmission systems are the smallest and lightest units that are approved by all the major commercial satellite operators. Key design features of the units include the ability to be carried and set up in minutes by one person (who is not expected to be a satellite communications specialist) irrespective of the location and the climatic conditions.

To achieve the required levels of signal accuracy (less than 3° of arc), portability and reliability, extensive use has been made of carbon fibre composites for the main reflector, the sub-reflector and the transit case.

The case lid, the main reflector (dish) and sub-reflector with its associated arm are supplied as structurally bonded, finished components by Carbonia Composites AB, based in Malmo, Sweden. The company specialises in the production of high precision, composite components using primarily carbon fibre, specially-formulated epoxy resins, DIAB's Divinycell core materials and a proprietary RTM process. It produces components ranging from exterior truck panels, to submarine battery containers, missile wings and car styling accessories.

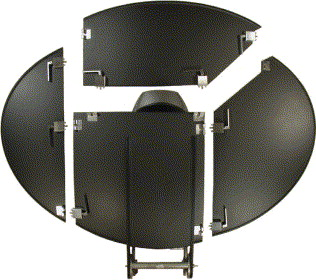

The requirement for the satellite system to retain its transmission accuracy under potentially very difficult operating conditions (including temperatures of -40°C to +100°C [-4°F to +104°F]) has meant that the three Carbonia components have to be manufactured to an overall tolerance of ±0.6 mm. (In fact, the sub-reflector is made to accuracy +0.05 mm.) Achieving this level of accuracy is further complicated by need for the main 900 mm diameter reflector (dish) to be dismantled into four separate pieces after use so that the system is truly hand-portable.

In the view of the Carbonia team, it would have been impossible to meet the operational parameters without the use of carbon fibre composites. No other material was able to offer the required levels of strength, stiffness and low thermal expansion and meet the target weight.

In addition to developing a special variant of its RTM process to achieve the required levels of component accuracy, Carbonia also designed and developed the special ‘latching system’ that locks together the four elements that make up the main reflector (dish).

The carbon composite satellite transmission system is designed so that the four elements can be locked together in just seconds without any adjustments being required, or for that matter allowed, in case the operator inadvertently introduces errors into the system.