The Aventador in action.

As outlined in our previous article Lamborghini: 30 years of carbon fibre, Lamborghini's use of carbon fibre composites in its cars has been growing. The company reports that in 2009 it it used around 100 tonnes of carbon fibre materials, a figure that will triple to more than 300 tonnes this year.

|

Since the 1980s, the average weight of our vehicles has increased by around 500 kg, due to the requirements set by safety, comfort and emissions reduction. This is a trend we must reverse with urgency. However, because we cannot sacrifice either safety or comfort, we will start using new materials. The magic words are carbon fibre. ... Every new Lamborghini will make use of this carbon fibre technology for optimum weight reduction. |

| Stephan Winkelmann, President & CEO, Automobili Lamborghini |

Lamborghini is currently producing the Gallardo and Aventador models at Sant’Agata.

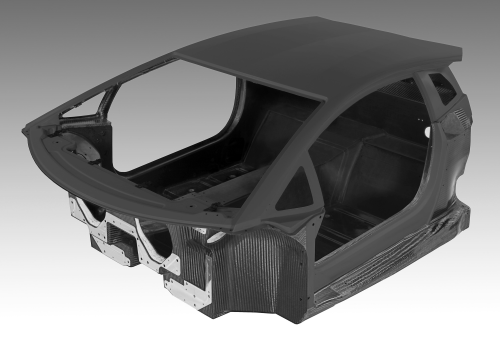

The Gallardo LP 570-4 Superleggera and Gallardo LP 570-4 Spyder Performante demonstrate targeted application of carbon fibre – on the bodyshell and in the interior – on an aluminium structure, while the Aventador, launched in 2011, features Lamborghini's first carbon fibre reinforced plastic (CFRP) monocoque structure. It also has a carbon fibre engine bonnet, movable spoiler and side air inlets. The front bonnet, front fenders and doors are aluminium. The rear fender and rocker cover are sheet moulding compound (SMC).

Aventador monocoque

Lamborghini reports that the Aventador is the only production car with a full CFRP monocoque (comprising the base section known as the 'tub' and the roof), and that it is the only company to manufacture a CFRP monocoque for a production vehicle in-house.

The carbon fibre monocoque ensures very high torsional rigidity and thus outstanding precision on the road, as well as an extremely high level of safety for the driver and passenger. (Formula 1 race cars have been built around CFRP monocoques for many years.)

The monocoque is made from a series of individual parts with specific functions. After the curing process, however, this structure functions as a single component.

The finished monocoque weighs only 147.5 kg (324.5 lbs). It is connected at the front and rear with rigid aluminium sub-frames, on which the suspension, engine and transmission are mounted.

The entire body-in-white (chassis) of the car weighs only 229.5 kg (505 lbs) and boasts a torsional stiffness of 35,000 Newton meters per degree. This guarantees extremely exact wheel control with excellent steering precision and sensitive feedback.

Composite technologies

Three main CFRP manufacturing methods are used in the monocoque.

Resin transfer moulding (RTM): In this process carbon fibre mats are preformed and impregnated with resin. They are cured under heat while the part is in the mould. In Lamborghini patented 'RTM-Lambo' process, the final mould is not a heavy, complex metal piece, but is made from lightweight carbon fibre composite, which makes the manufacturing process faster, more flexible and more efficient. An additional benefit of the RTM-Lambo process is a low injection pressure that doesn’t require expensive equipment.

Prepreg: The carbon fibre prepregs are cut to shape, positioned in moulds and cured under heat and pressure in an autoclave. Prepreg components are complex to make but have a high-quality (Class A) surface finish and are Lamborghini's preferred option for parts that are visible.

Braiding: This carbon fibre weaving technology is derived from the textile industry and used to make tubular components for special applications such as structural roof pillars and rocker panels. The braided structures are processed using RTM.

Epoxy foam components are also used within the monocoque. These are placed at strategic locations to increase the stiffness of the monocoque; they function as spacers between the composite layers while also dampening noise and vibration. In addition, aluminium inserts are laminated into the front and rear surfaces to facilitate connection with the aluminium front and rear subframe elements.

Production line

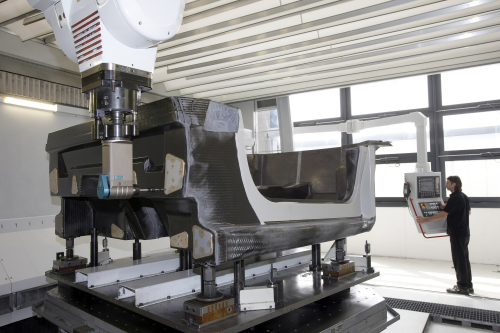

Because of the complexity of the materials and processes it wanted to use, Lamborghini decided to produce the Aventador monocoque itself. A 5400 m2 production facility was built at Sant’Agata for the production of the monocoque and the complete body-in-white of the car.

The production facility is organised into five lines:

- The prepreg parts are made on the first line. This operation requires a high level of manual labour and the parts are cured in an autoclave;

- On the second line, parts and sub-assemblies are made using the RTM process. This process is highly automated. Curing takes place in a heated chamber. This is also where the prepreg parts from the autoclave and the epoxy foam parts are integrated into the RTM monocoque structure;

- The third line is where the epoxy foam stiffening components are produced. These components are then assembled as inserts into the prepreg and RTM parts;

- On the fourth line the monocoque structure and the roof are machined, assembled together and measured; and

- On the fifth line, the finished monocoque is connected to the aluminium front and rear sub-frames and all exterior bodyshell parts to create the finished bodyshell.

The prepreg line starts with the automated cutting of the material, using a computer-controlled cutting machine located in a climate-controlled room. The subsequent positioning of the prepreg in the moulds is handled by experienced specialists. After vacuum bagging, curing takes place in two autoclaves which operate at a pressure of 6 bar and a temperature of 135°C.

The RTM line commences once the dry fibre patterns have been cut, with an automated preforming process.The preformed fibre mats are joined together in their final form on the tooling, where the positioning process is handled by lasers. The tooling is closed and resin injection starts, followed by curing at around 100°C.

| In the RTM-Lambo process, the moulds are made from carbon composite instead of steel. |

In the RTM-Lambo process, the moulds are made from carbon composite instead of steel. In some cases, the component just completed serves as the 'mould' for the next step in the process, to which the additional parts are simply added and co-cured.

Lamborghini worked with its suppliers to develop exclusive fibre and resin systems for its RTM technology.

Every monocoque is measured to exacting tolerances of only 0.1 mm.

On the assembly line, the monocoque is connected to the aluminium subframes and additional parts ranging from the front spoiler to the rear diffuser. At this point, every vehicle is measured in its entirety. The automatic precision measuring system works partly with lasers and partly by touch.

Surface quality is ultimately checked in a light tunnel by trained specialists. Finally, the body-in-white is signed off for painting and for full vehicle assembly.

Research centres

The patented RTM-Lambo process was developed at the company's Advanced Composite Researc Center (ACRC), also located at Sant'Agata. More than 40 people work here to develop vehicle components, build prototypes and tooling, and derive concepts for optimum production methods.

The ACRC comprises two facilities: the Prepreg Centre, where production methods using autoclaves are perfected; and the 'Out of Clave Centre', where work is focused on technologies that do not require the use of large-scale autoclaves.

Tthe ACRC also develops repair techniques for CFRP structures (see Lamborghini's 'flying doctors' take care of carbon fibre repair), and simulation technologies to calculate the mechanical performance and crash behaviour of CFRP components.

Lamborghini also has a research centre in the USA. At the Lamborghini Advanced Composite Structures Laboratory (ACSL) at the University of Washington the car maker works with its US research partners, including Boeing and Callaway Golf.

Over the years Lamborghini has amassed numerous patents relating to carbon fibre technology, including the RTM-Lambo process, the monocoque assembly concept, and the self-heating tools used in the RTM process. Further patents are in the approval process, as the company strives to strengthen its position in CFRP. ♦

Also see:

This article was published in the September/October 2013 issue of Reinforced Plastics magazine.

The digital edition of Reinforced Plastics is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing the registration form.