When the first multi-megawatt (MW) wind turbine prototype was built in the early 1980s, the wind energy industry saw its future. And it was big.

The prototype proved that 2-3 MW turbines could reliably deliver a magnitude more energy over a lifetime than their 300 kilowatt (kW) predecessors. The industry could increase yields, decrease cost per kilowatt hour (kWh) and become a more competitive energy source by making turbines progressively larger. This insight, combined with the exploding demand for 'green' energy alternatives to decrease reliance on fossil fuels, meant 'big' would be the next big thing.

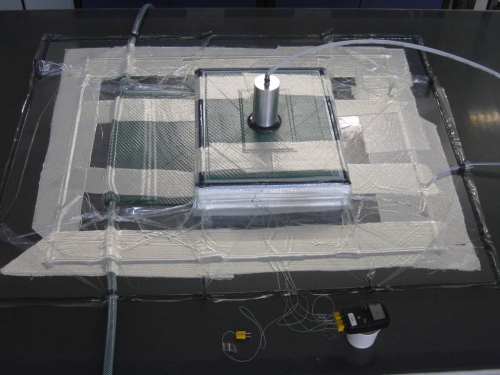

The success of the prototype also ushered in a new generation of materials. As blades increased in length from less than 20 m to greater than 26 m, epoxy resin systems began to replace polyester resins and have since become the standard matrix resin for longer blades. In addition, although glass fibre is strong enough to handle the stresses exerted on the longer blades required for a 3 MW turbine and most multi-MW turbine blades are still being built with glass, carbon fibre-based epoxy resin composite materials could provide the required mechanical strength while minimising additional weight. Years of research and development into these raw materials followed. This work continues today and promises to accelerate as the demand for wind energy explodes, and the need grows for ever larger turbines powered by ever longer blades.

The challenges which this has placed on blade manufacturers and their resin suppliers are many. We’ll try to identify the key issues both historically and on the horizon.

This is an extract from a feature published in the January/February 2010 issue of Reinforced Plastics magazine. You may download the complete feature here at no cost.